Ironmaking raw materials account for 65% of the total cost of steel mills that have always operated. In addition to mastering the material source price, finding the ratio that meets quality standards at the lowest cost can effectively reduce the total cost of the steel mill and increase profit margins.

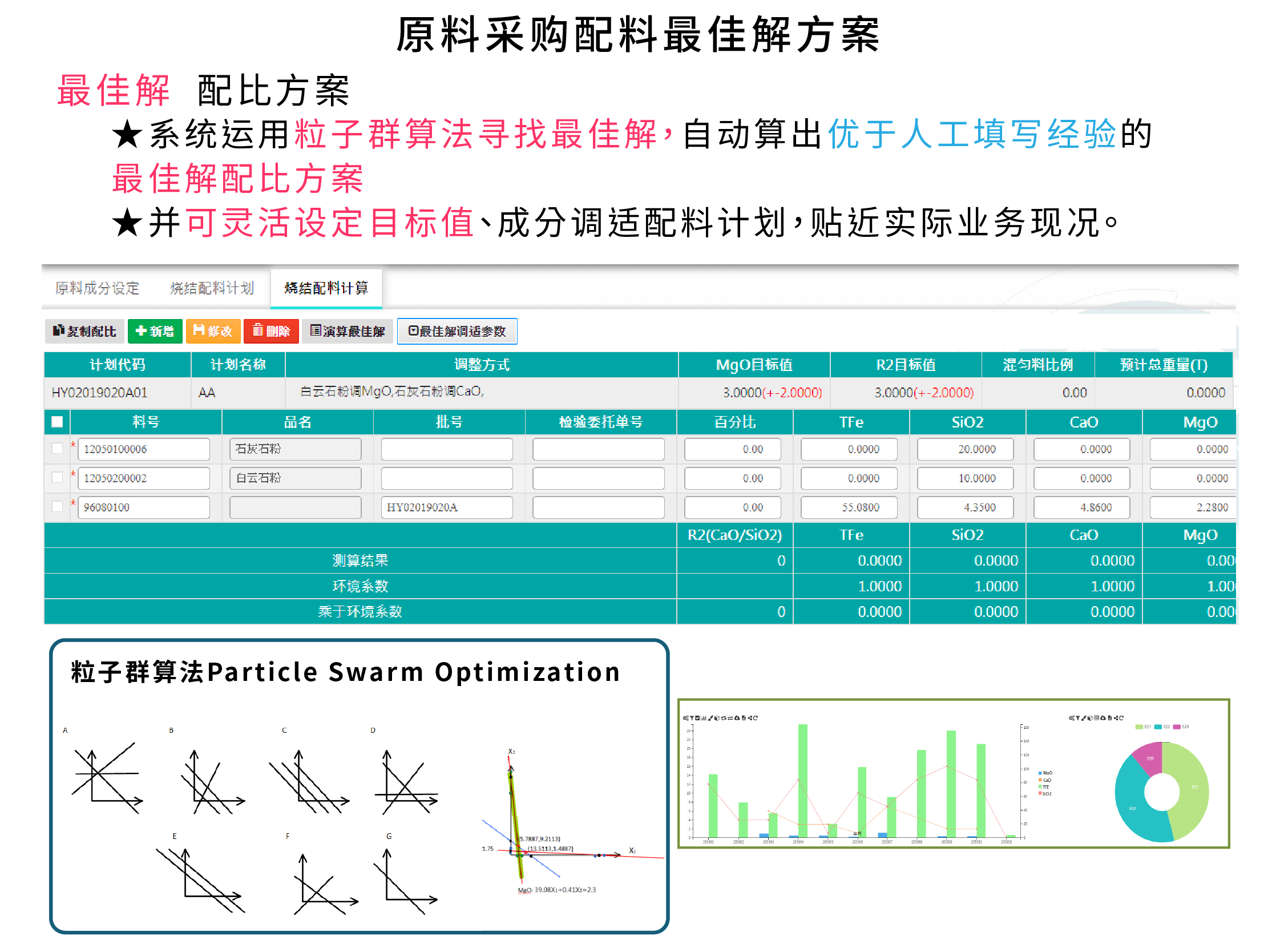

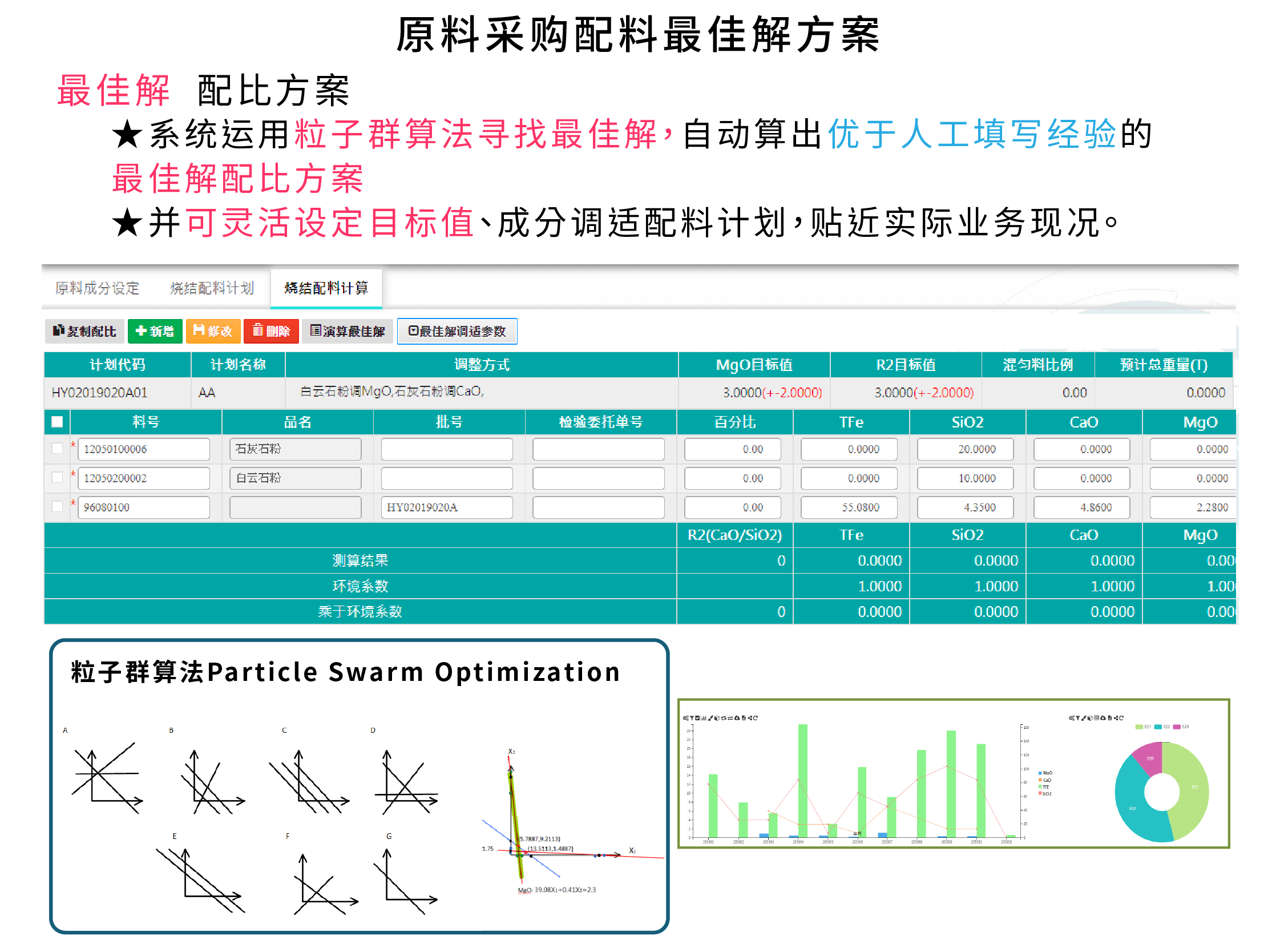

The intelligent iron ingredient raw material ingredients system is the intelligent ingredient system developed by Zhongguan Information based on the pre-iron MES system, in response to mastering the quality of molten iron and finding the lowest cost ratio. Under the data of raw material inventory quantity, quality and cost unit price in the integrated factory, the quality requirements of mixing, sintering and blast furnace production are hit, and the calculation is based on algorithms to present the best solution for the lowest cost.

Combined with environmental impact coefficient, accurate hit quality indicator requirements

The proportions of various stones can be calculated based on the optimal mixing ratio.

Supports the calculation of the lowest cost solution based on the cost of the care source

Through ingredient calculation, the system can calculate the best ingredient ratio in mixing, sintering and blast furnace ingredient calculations; and support the lowest cost solution can be obtained directly based on the cost of the care source.

The production plan of the iron area is mainly formulated based on the capacity plan, and the goal is to ensure stable production of iron smelting and sintering production. During the production process, the system automatically links the data of the operation management module, compares the production plan with the actual performance, and grasps the implementation of the ingredients plan.

Cost reduction: The cost per ton of sintering ratio is reduced by about 50 yuan compared to manual ratio

Quality improvement: Ensure that all quality components hit the target by 100%

Performance tracking: Ingredient measurement and performance complete online tracking