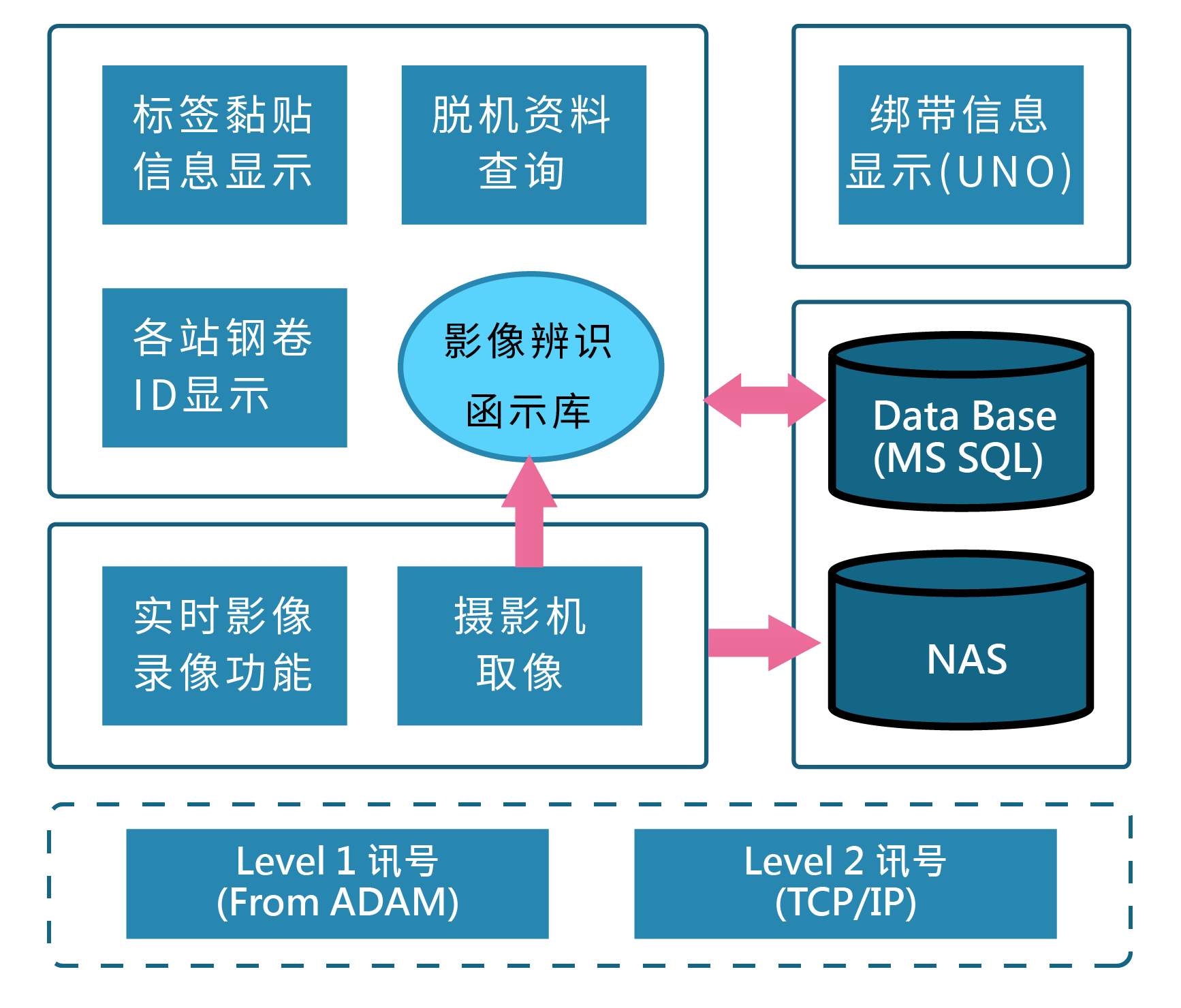

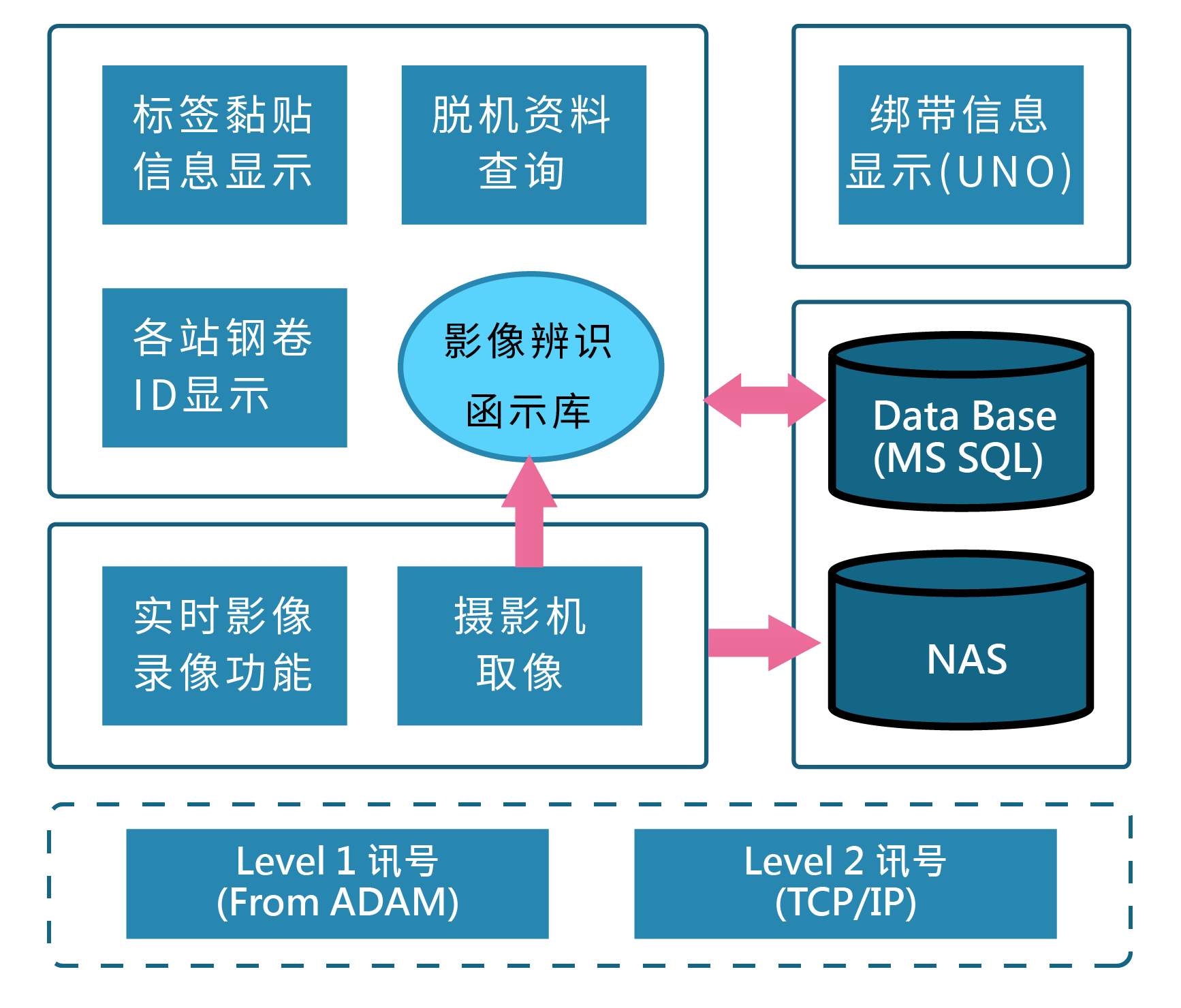

During the process, mixing is occasionally generated in the logistics/data flow. Once more than two order errors occur, in order to reduce the chance of mixing and improve customer satisfaction, AI is used to automatically identify the coil ID to strengthen process management capabilities.

On-site moving lines on the steel coil, such as: the entrance, unwinding machine and exit of the steel coil production line, digital high-quality cameras are installed to store image data during the steel coil production process, and image processing algorithms integrated with three methods such as neuro-like artificial intelligence, sample comparison (Patten Match) and geometric comparison technology (Geometry Match) are used to identify the ID of the steel coil, build a quality tracking system, strengthen logistics/data flow management capabilities in the process, reduce the chance of mixing and improve customer satisfaction.

Establish an automatic identification mechanism for steel coil ID

Improve the management capabilities of process materials and data flows

Position detection: Automatically detect the actual position point within the image pickup range and the steel coil number

Number detection: After the positioning is completed, the system will identify the steel coil number and automatically turn it into the positive.

Data management: Return the identification results to the secondary system or store them in the database for inspection

Detection warning: When a data inconsistent occurs, the system will issue a warning notification to the operator to intervene in the processing.