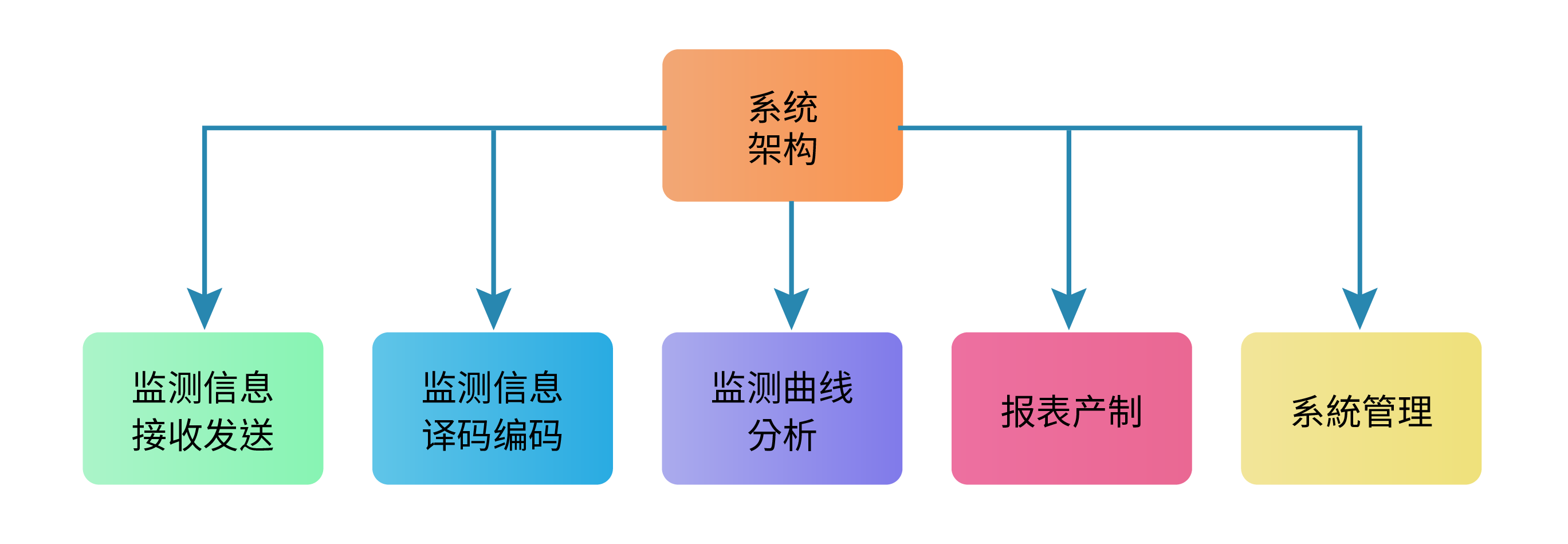

The flue gas continuous emission monitoring system is a tool that has been implemented for a long time at home and abroad. It has real-time and continuous monitoring functions, allowing manufacturers and government units to grasp the emission situation of pollution sources and the operation of pollution prevention and control facilities in real time, and serve as the basis for calculating and reporting air pollution prevention fees.

The CEMS system can provide various environmental statistics and operation reference information. Through the combination with production information and the analysis of big data, it is an important tool for process optimization and management, and it is better than laws and regulations and economical and environmentally friendly operation mode. CEMS has become an important management tool that takes into account both economic and environmental benefits.

Comply with the latest announcement of the Executive Yuan Environmental Protection Agency's "Management Measures for Continuous Automatic Monitoring Facilities of Fixed Pollutants" and "Continuous Automatic Monitoring Facilities of Fixed Pollutants" and "Continuous Automatic Monitoring Facilities of Fixed Pollutants"

I/O module interface can support RS232/RS485, ModBus and ModBusTCP

Test value exceeding limit settings and alarm sound prompts

Automatic or manual correction function

Automatically backup of raw data, no missing data, comply with regulations

When the instrument correction offset rate is greater than the legal value, you can reset whether to make up for correction.

Computer and I/O communication module interrupt warning reminder

Comply with regulations to monitor frequency

Monitoring system backup function

Supports Windows 64-bit working environment

Real-time, daily, monthly reports, monthly report data and declaration documents upload and report

Calculate emissions in accordance with the latest provisions of laws and regulations

The system can calculate the current monthly efficiency and estimate the regulatory margin

The system can be used to indicate the starting and shutdown of the furnace...

Various related internal management reports (efficiency, daily correction) including transfer EXCEL function

BAF settings

RATA data export and import

Automatic retention and backup of declaration data

Automatic timing writing and setting, which can adapt to various types of monitoring instruments

Automatic recompense and recalculation of disconnected data

Manual interval recalculation and substitution to the Environmental Protection Bureau