China Steel Corporation is the largest steel company in Taiwan Province, with an annual output of rough steel of about 10 million metric tons. It is a stable and down-to-earth enterprise. In 2023, China Steel proposed the new vision of "smart innovation, green energy carbon reduction, value co-creation, becoming an outstanding enterprise for sustainable growth", and listed "digital transformation" and "low-carbon transformation" as key tasks, and implemented the dual main axes of "high-value exquisite steel mills" and "developing green energy industry". Data is the key to digital transformation, so we must discover more key data and achieve the application of intelligent manufacturing through artificial intelligence. However, data transmission can be divided into two ways: fixed network and wireless, and 5G is the most reliable wireless network because 5G has deterministic network specifications, with high bandwidth, low latency and wide connection characteristics. Therefore, in June 2011, China Steel Corporation implemented the 5G AIoT project through its R&D department, and cooperated with ICSC Information to build a high-reliability and high-security 5G industrial control environment and applications such as ICSC.

On 112/02/16, the NCC led a delegation from the Vice Chairman to China Steel Company to visit the 5G AIoT application results on the spot, and stated that the government and industry are actively using 5G high-speed, low latency, wide connection and other characteristics to develop various innovative applications in the industry.

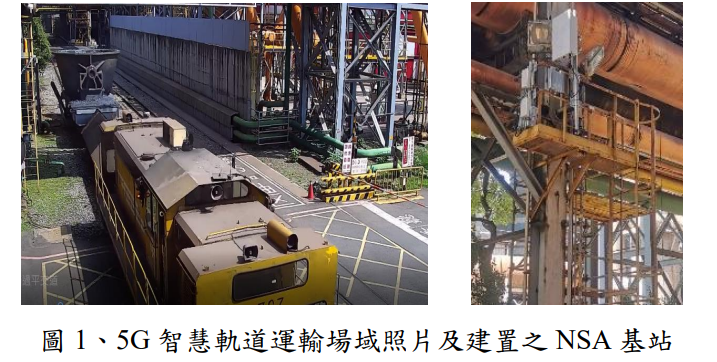

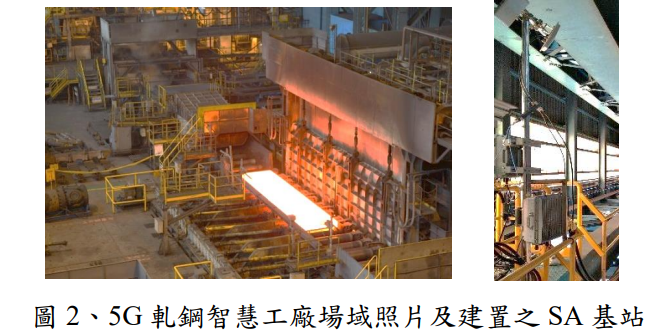

China Steel Corporation has completed an outdoor, an indoor demonstration field and a 5G application laboratory: the outdoor field carries out 5G smart rail transportation project, and cooperates with China Telecom to build a 900-meter-long 5G non-Standalone (NSA) signal, which is based on 4G LTE equipment (EPC and eNB), and is composed of 5G gNB base stations. The consideration for choosing an NSA architecture is that the technology is mature and the 4G coverage is wide and can be quickly deployed. Therefore, the demonstration plant completed the launch of 5G signals in December 2011. Indoor fields, the 5G steel rolling smart factory project is implemented, and it cooperates with Renbao and Cisco to build a 5G independent networking (Standalone: SA) signal, which can manage 10,000 door numbers and use N79 enterprise-specific frequency band (4.8GHz) to achieve the goal of not interfering with commercial frequency and dedicated frequency. First, the demonstration case development will be carried out through the 500-meter-long production line of the hot-rolled factory. In the future, the nuclear network can serve the entire group and expand the benefits in parallel. After actual measurement, the upload and download bandwidth of the two fields can reach 150Mbps and 500Mbps, which is about 6 to 7 times the 4G bandwidth. 5G's CT (Communications technology) network segment is used to transmit process data and decision-making information, so it will span IT (Information technology) and OT (Operation technology) network segments. Security protection is the primary topic. The commission asked Lu Zhu Telecom Research Center to assist in designing a "front monitoring and rear control" security protection architecture. CT enters the boundaries of IT and OT, and uses physical firewalls to protect it. The CT network segment adopts monitoring methods to avoid affecting the low-latency characteristics of 5G.

In terms of application, nine intelligent manufacturing application projects have been completed (intelligent plate embryo dynamic monitoring, steel belt offset monitoring system, expert remote collaboration system, digital production line real-life guide, remote control of dangerous operations, slag bucket status monitoring system, driving safety assistance system, XR virtual reality training, and self-propelled vehicle technology development). Briefly describe the necessity of introducing 5G for four intelligent manufacturing projects.

Remote control of hazardous operations: In the high-temperature areas of the steel industry, there are industrial safety risks such as high heat and splashing. In areas that cannot be automated, they should still operate through manual means. Therefore, operators try to stay away from hazardous operations areas, but their perspective is limited and it is difficult to accurately control. 5G's large bandwidth and low latency characteristics can return on-site images and data, providing a complete perspective of operators, greatly reducing risks and improving operational efficiency.

Driving safety assistance system: When a vehicle moves for a long distance, it must transmit driving images and data back through the wireless network to truly grasp the vehicle dynamics. Import 5G as a long-distance wireless transmission tool, presents driving images outside the dispatching center, and uses artificial intelligence image recognition to assist driving to monitor the vehicle status, greatly improving driving safety.

Expert remote collaboration system: Digital transformation can change the way and speed of decision-making. When problems occur on the site in the past, they can only discuss with experts in oral form, or wait for experts to come to the site for guidance, expand the degree of equipment damage or waste time costs. Develop expert remote collaboration system APP, use tablets or mobile phones to hold video conferences anytime and anywhere through 5G network, and provide on-site image and process data, allowing experts to make decisions together and minimize damage.

Real-life guide for digital production lines: Virtual reality (VR, AR) technology has flourished in recent years, emphasizing immersive experience. China Steel Company has many VIPs visiting each year, so it has developed a virtual hot-rolled production line to provide another guided experience through digital glasses or tablets, which can be used as the basis for training or digital twins for new recruits in the future. 5G is used as a transmission tool for digital models.

According to the International Telecommunications Standard (3GPP), the R15 version released currently focuses on the application of major bandwidth characteristics, while the R16 version focuses on the characteristics of low latency. Although the R16 specification was released in July 2020, there are only equipment that has been developed and completed in the near future. Therefore, China Steel Company's subsequent research direction will be aimed at high-speed mobile 5G remote control applications, and the technology of 5G large bandwidth transmission can be expanded to other fields.

2023-02-01

2023-02-01 Collaboration News

Collaboration News 上一篇

上一篇