Preface

With the development of science and technology, production equipment is becoming increasingly new, and high-tech equipment has brought reforms to many steel companies in production rhythm and efficiency; but with the increasingly fierce market competition, various companies' attention to products has changed from "having" output to "excellent" good products: pay more attention to steel quality, customer delivery requirements, and ability to control production costs.The following will illustrate the development of steel companies in steel mill production intelligent scheduling based on three topics: the demand assessment, implementation difficulties, and intelligent solutions of production schedules.。

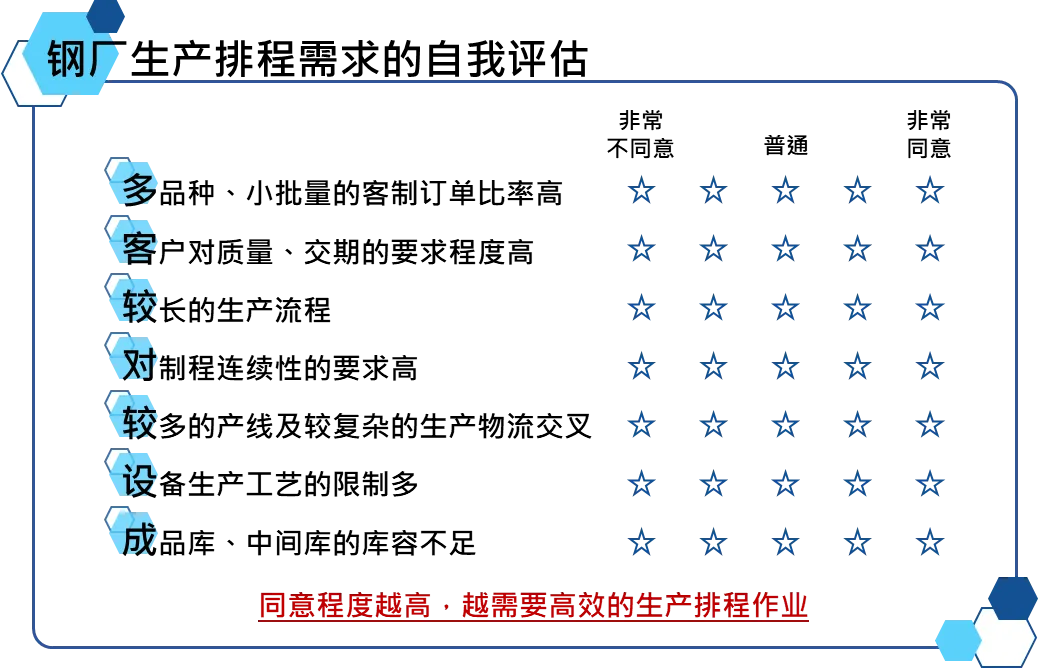

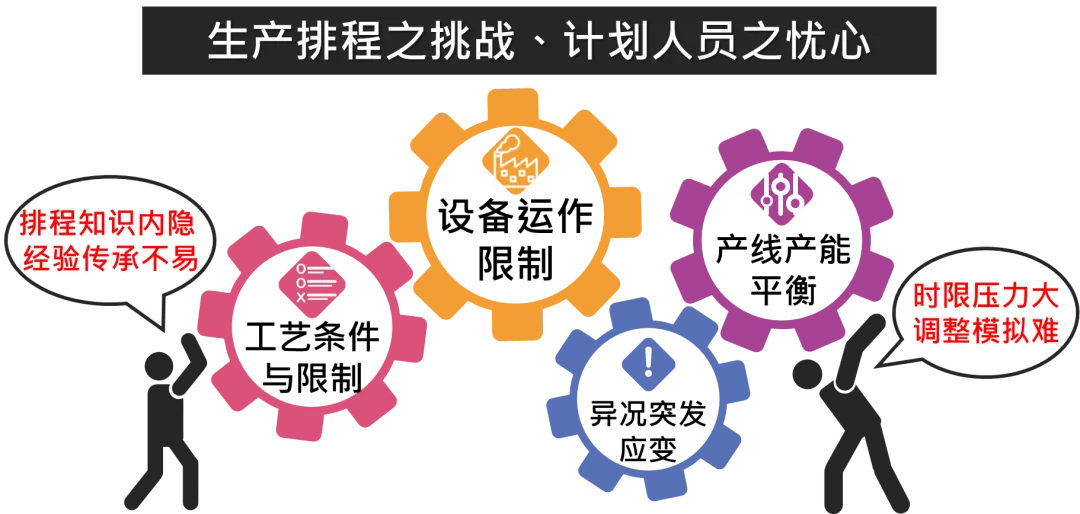

The evolution of steel mill production scheduling role In steel mills that are mainly ordinary steel and have simple specifications, they only need to balance the production line between molten iron, steelmaking and steel rolling during the construction period. After production, the production plan can be led by the sales department to promote smooth production. However, with the increasing market competition and the increasing demand for high-quality steel, the initiative of "determining production based on sales" has been pushed forward to customers. Customers' requirements for steel specifications, sizes, packaging, quality and delivery time are becoming increasingly strict, forcing enterprises to establish a more complex production scheduling mechanism from the production supply side, and invest a large number of scheduling personnel in the production planning office and workshops to alleviate various production bottlenecks, complete the balance of output, delivery time and cost, and make quick scheduling decisions in response to various sales orders, equipment shutdowns, and quality conditions. The efficient operation of production planning and scheduling has become the decisive factor for steel mills to gain customers, increase output value and reduce costs. Self-assessment of steel mill production scheduling needs The main purpose of production scheduling is to balance various conditions and goals and eliminate production bottlenecks. Steel companies can evaluate whether efficient production schedule operations are required from the following diagrams: The goals and difficulties of steel mill production schedule (1) First of all, the workshop must consider complex factors such as the operation limitations of their equipment, production process limitations (such as the impact of roller diameter switching order on quality), efficiency and cost reduction (such as furnace rate, material formation rate, residual material rate) and other complex factors. (2) Secondly, the production balance across the workshop (such as the consistency of converter, refining, continuous casting, and hot rolling to avoid idleness or breakage), minimum cost (such as heat inlet and heat transfer rate to reduce energy consumption), intermediate inventory (such as the storage blockage). (3) Finally, and the most complex difficulty is that new schedules must be quickly prepared to support the achievement of the overall goal (KPI) of the production schedule (KPI) at any time in response to sales orders, equipment failures, and production quality conditions. Manual scheduling: Two worries that I don't want to admit it and cannot bypass (1) An excellent planner needs to be cultivated for many years and undergo various conditions, but valuable knowledge and experience can only be left in the planner's mind. The planner's leave request, position change, and resignation all affect the results of production schedules and cause significant losses to output, delivery time and costs. (2) In the tense production rhythm, the pressure of time only allows the planner to adopt a set of scheduling strategies to propose one scheduling result, and there is no time to try to adjust the simulation plan and compare the benefits of each scheduling result. The avoidable but unavoidable costs and the benefits that can be fought for but not strive for have become a long-standing and tacit question for everyone. Intelligent Schedule: The four most important indicators of the intelligent scheduling system in the steel plant

2021-10-19

2021-10-19 ICSC News

ICSC News 上一篇

上一篇