ICSC EZoMQ: High availability manufacturing data exchange solution - a data bridge for steel giants

In the precise operational territory of steel manufacturing, every data flow is the blood of production efficiency and decision-making wisdom.Faced with the bottlenecks and challenges in traditional data exchange solutions, ICSC has launched a high-availability data exchange solution tailored for the steel manufacturing industry with its profound industry insights and technological innovations, ensuring that your company is as stable as a rock in the data torrent and accelerating the pace of smart transformation.

1. Accurate response to core pain points

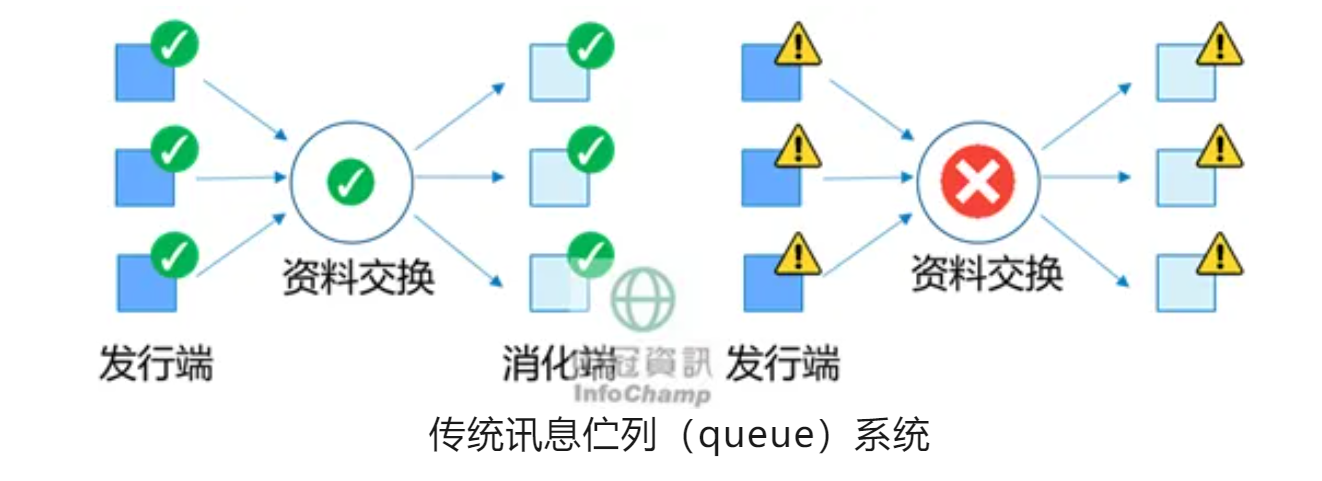

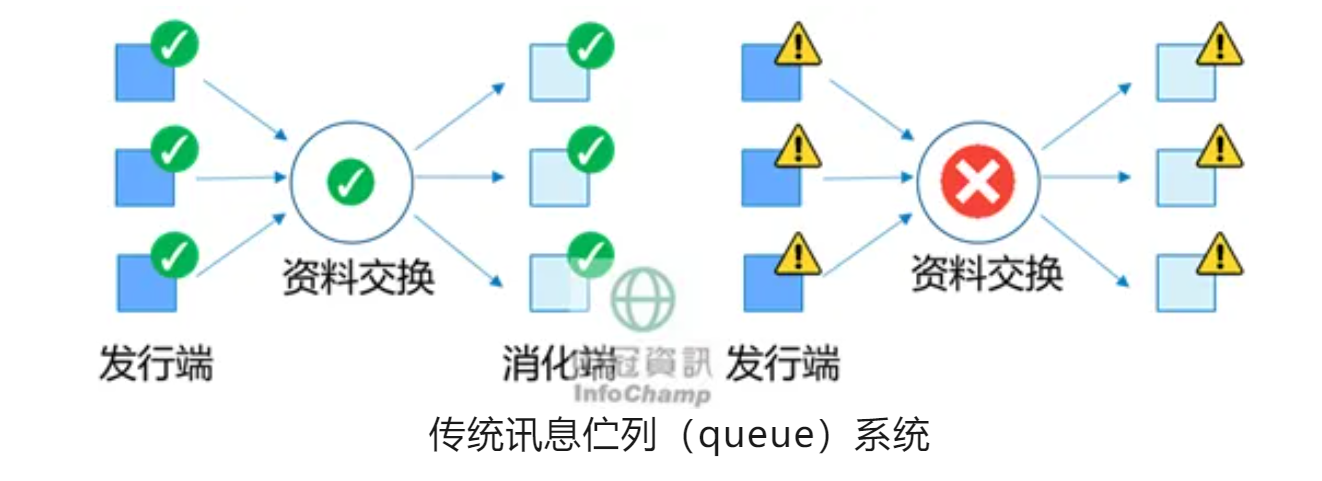

Traditional data exchange systems are often limited by the risk of hardware failure, and an unexpected hard disk corruption or host failure is enough to put the entire factory's information system to a standstill. ICSC is well aware of this pain and carefully designed a data exchange platform without single point of failure to ensure that even in the most unfavorable circumstances, the continuous circulation of information can be guaranteed and economic losses caused by production interruptions can be avoided.

Second and third pillars to build the foundation stone of high availability

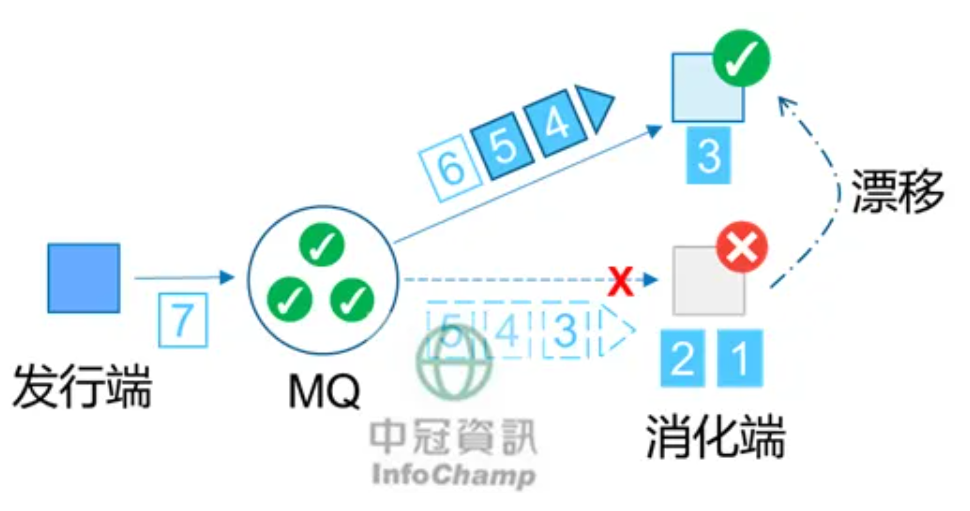

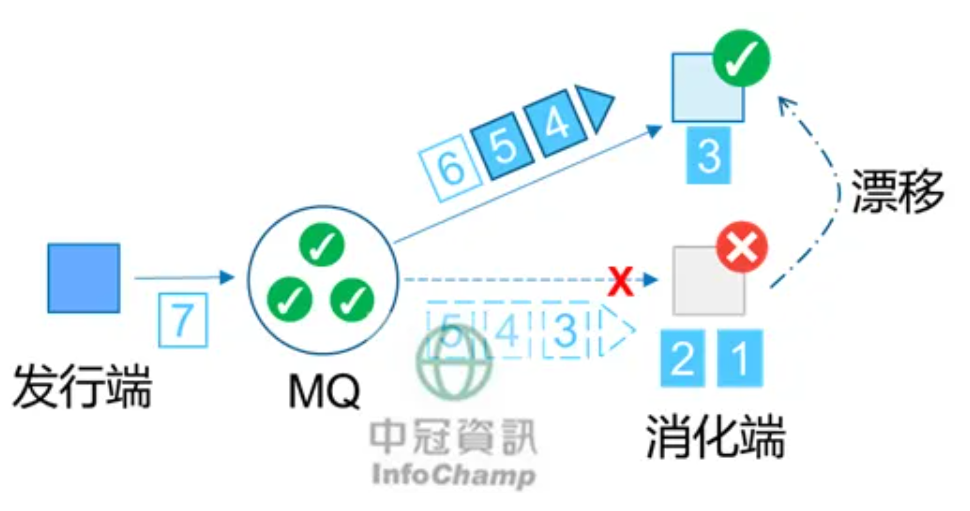

1. Decentralized cluster architecture, solid core of data exchangeUsing advanced distributed cluster rack design, a high-availability data exchange center containing at least 3 independent nodes is built.This layout can seamlessly maintain the system operation even in the face of sudden failures of 1-2 nodes, ensure the continuity and stability of data exchange, and provide a solid backing for your production line.2. Intelligent digestion end, elastic response uninterrupted Supports the multi-digesting node hot backup mechanism. Once the main digestion node encounters a failure, the backup node immediately relays, realizing zero-delay data takeover and breakpoint continuous transmission, ensuring the complete data sequence and providing timely and accurate information support for every link of the production process.

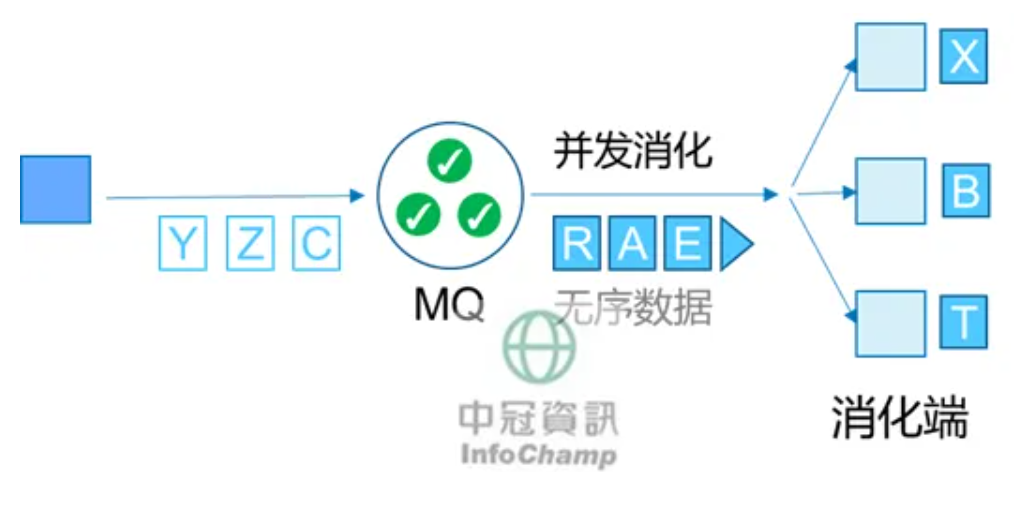

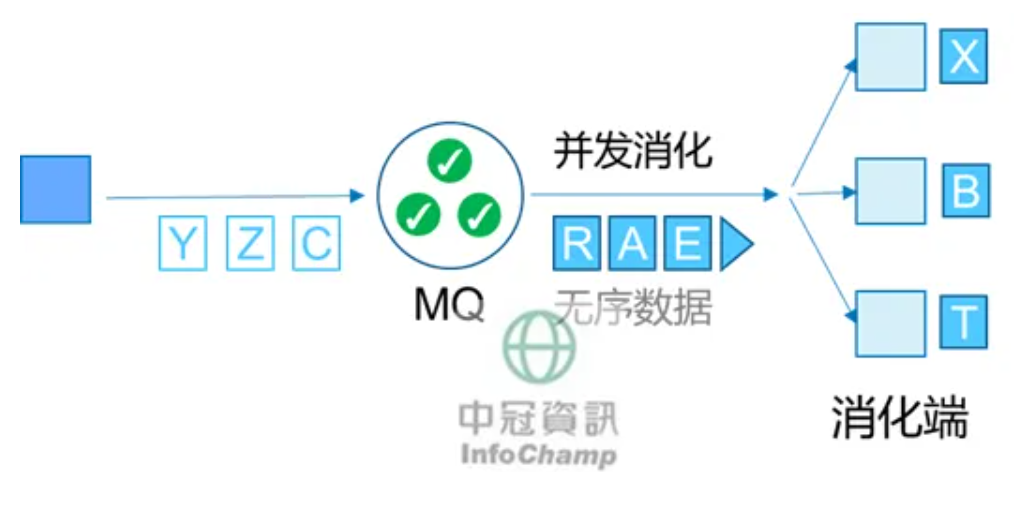

3. Efficient concurrency, unleashing data potential

In response to the processing needs of disordered data (such as basic main data, logs, etc.), we use multi-machine concurrent processing technology to maximize the utilization of hardware resources, and even large files can be delivered quickly, greatly improving data processing efficiency, and making data a powerful driving force to drive enterprises forward.

3. Centralized control, simplify the complexity

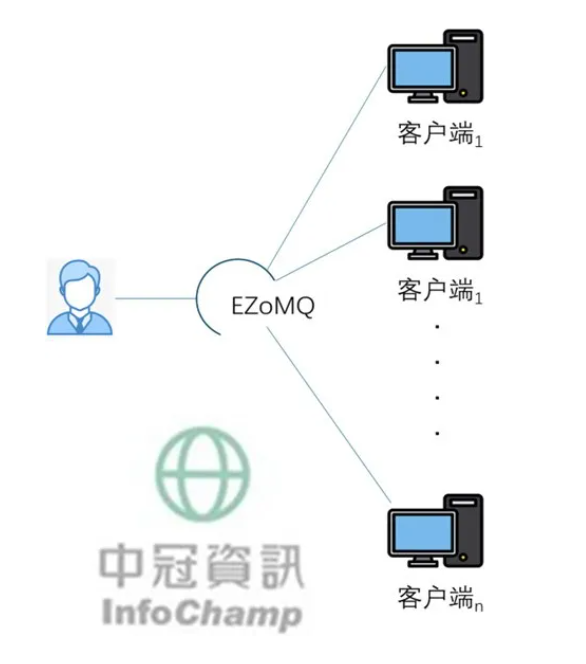

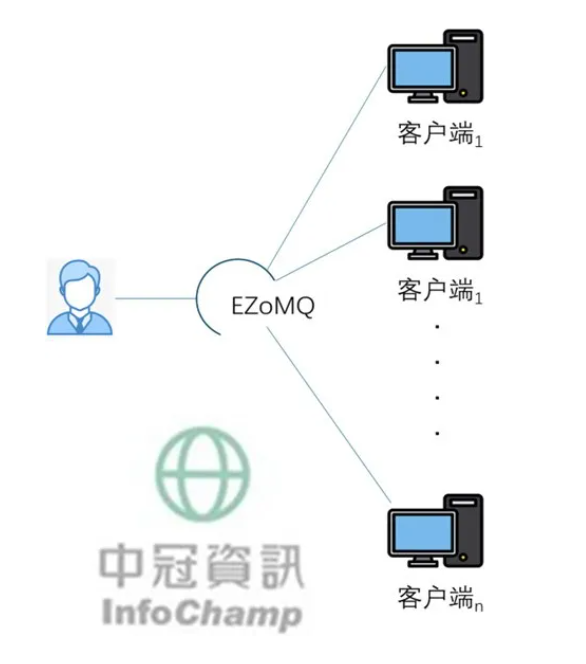

ICSC Solution is also equipped with an intuitive and easy-to-use centralized control client, allowing IT managers to easily complete node addition and configuration management of all users on a single interface. This design not only reduces the difficulty of system maintenance, but also promotes communication efficiency between teams, reduces the time cost caused by configuration errors, and allows enterprise resources to be optimally allocated.。

4. Paving the way for the future smart factoryThis plan is perfectly connectedERPandMESSystematicPDO/PDIThe interface provides strong support for the acquisition and processing of instant big data. Whether it isSPCStatistical analysis, equipment status monitoring, or smart factories and the Internet of Things(IoT)With a comprehensive advancement, ICSC High-available data exchange solutions are your indispensable partners, helping enterprises seize the initiative in the wave of digitalization.Comparison of differences before and after use of products

Product usage benefits – high availability and easy management

Choosing ICSC means choosing a trustworthy data management expert to give your steel manufacturing business efficient and reliable data wings and soar in the vast sky of intelligent manufacturing.

2024-11-08

2024-11-08 ICSC News

ICSC News 上一篇

上一篇