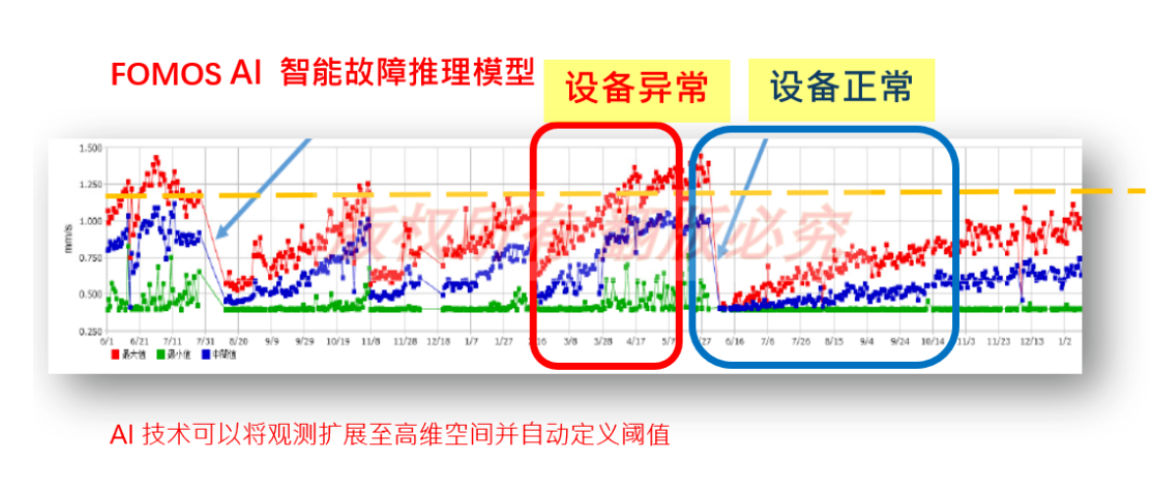

The construction of a monitoring system predicts the deterioration trend of equipment and avoids predictable abnormal shutdowns.

Monitor core equipment of the production line to reduce the impact of sudden downtime.

Plan the maintenance plan in advance in accordance with the monitoring system to avoid abnormal equipment failures.

Observe the equipment status in real time and reduce the manpower and material costs invested due to abnormal shutdowns.

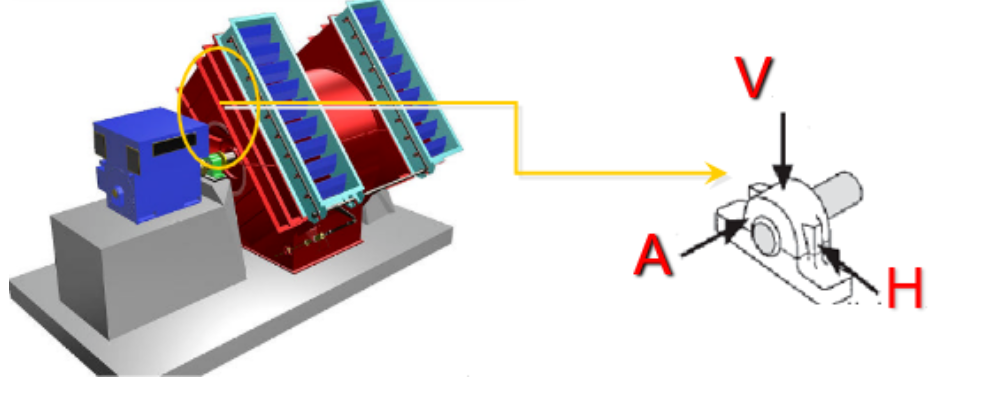

Equipment vibration measurement method

VibratemoveSensors convert equipment vibration signals into electrical signals that can be processed. It is very important to select appropriate sensors based on equipment characteristics and diagnostic purposes. Sensors for vibration measurement are divided into three categories.

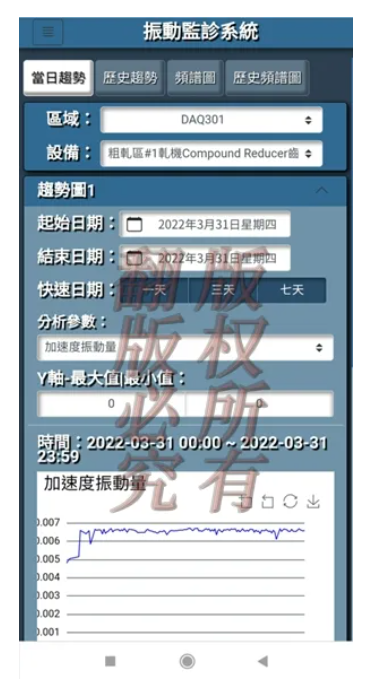

FOMOS equipment monitoring software-web version

FOMOS equipment monitoring software-mobile version

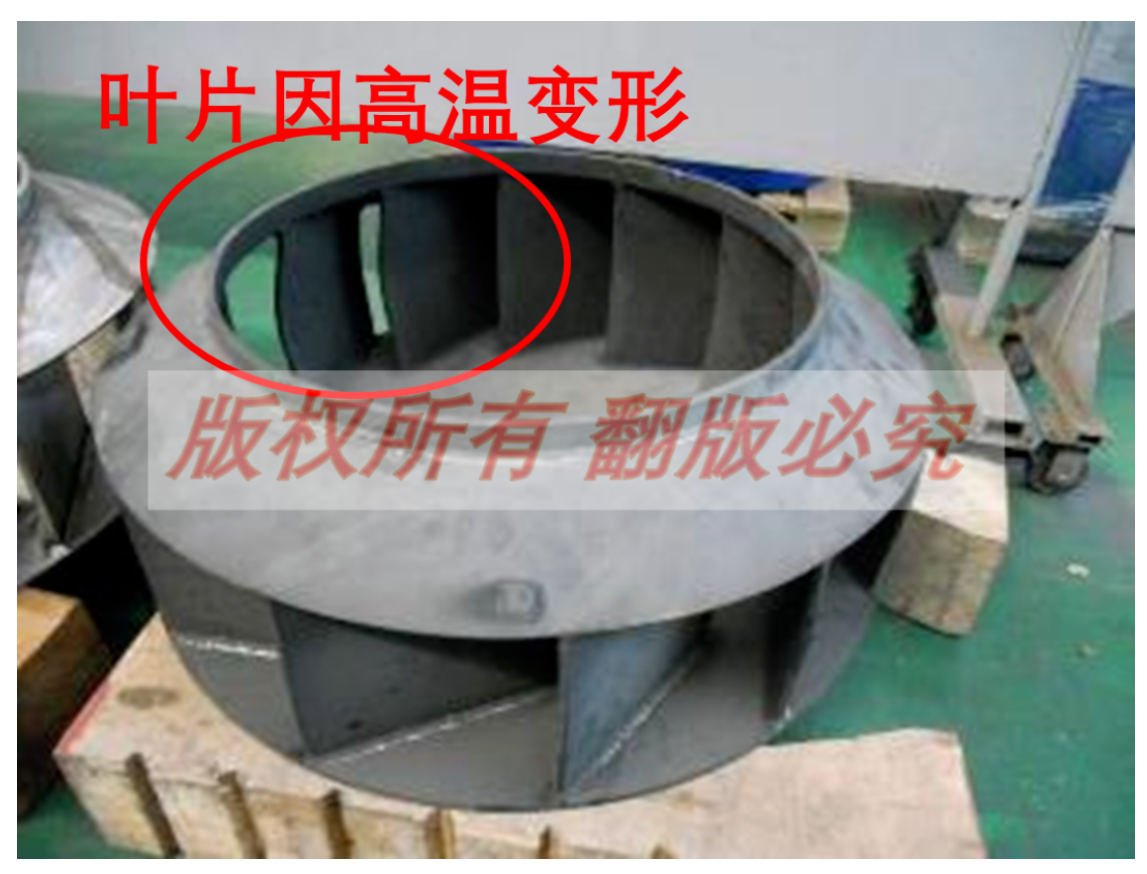

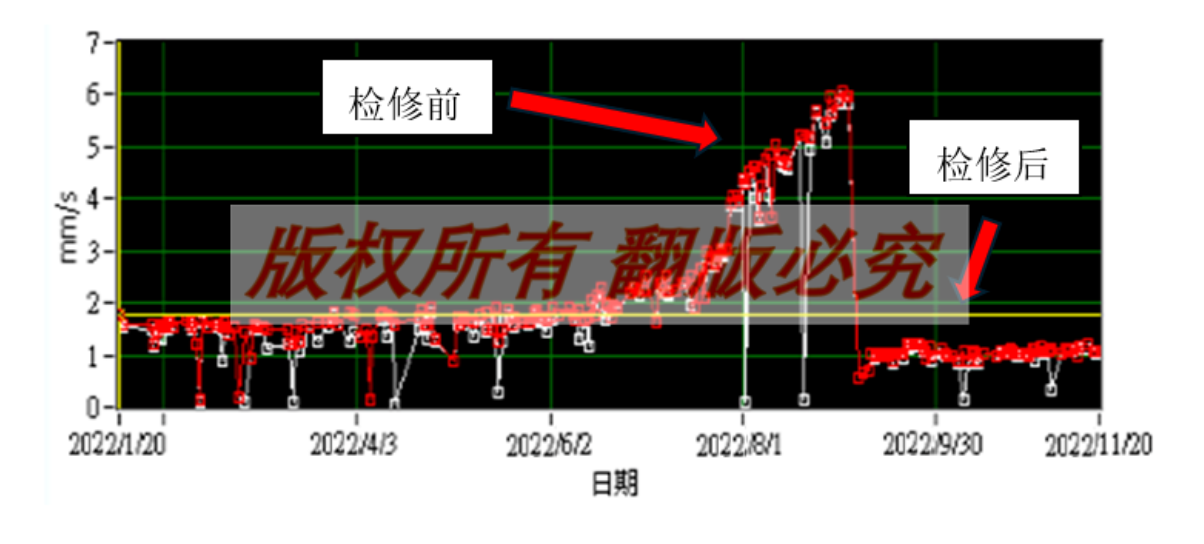

Application Case 1 Fan Balance Abnormal

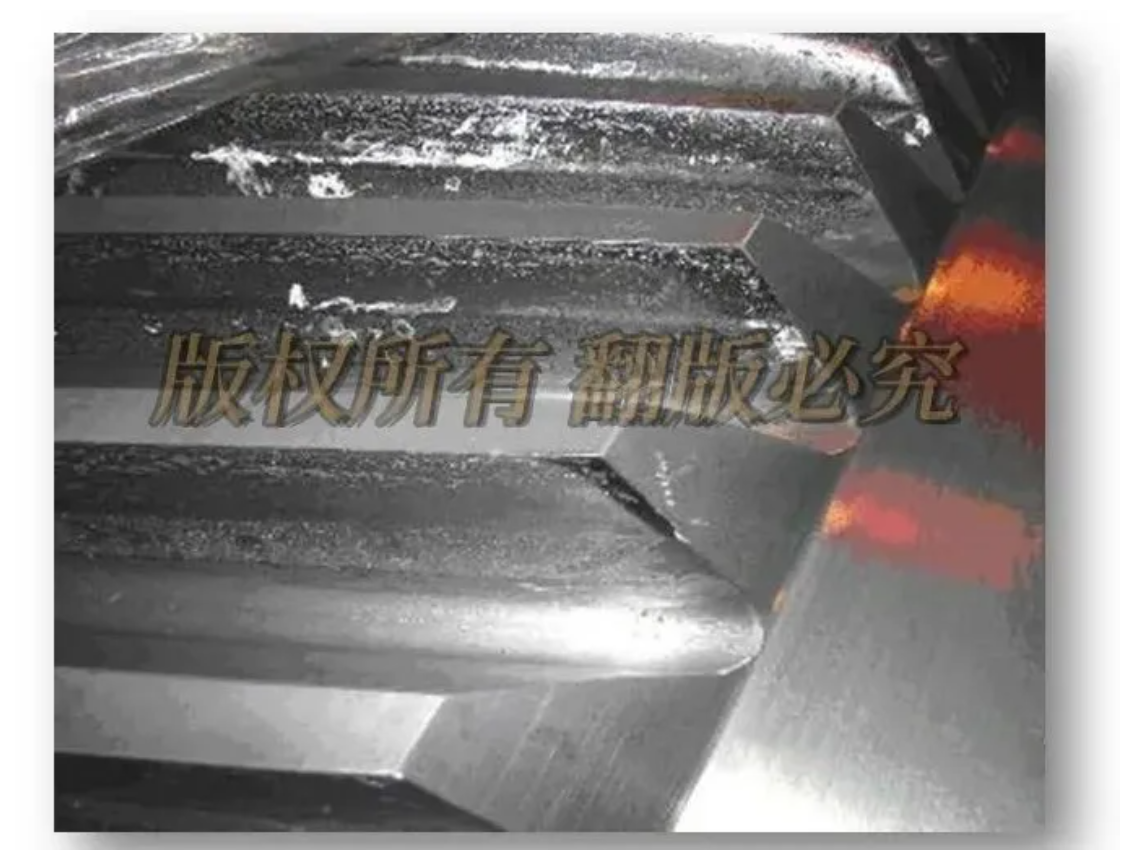

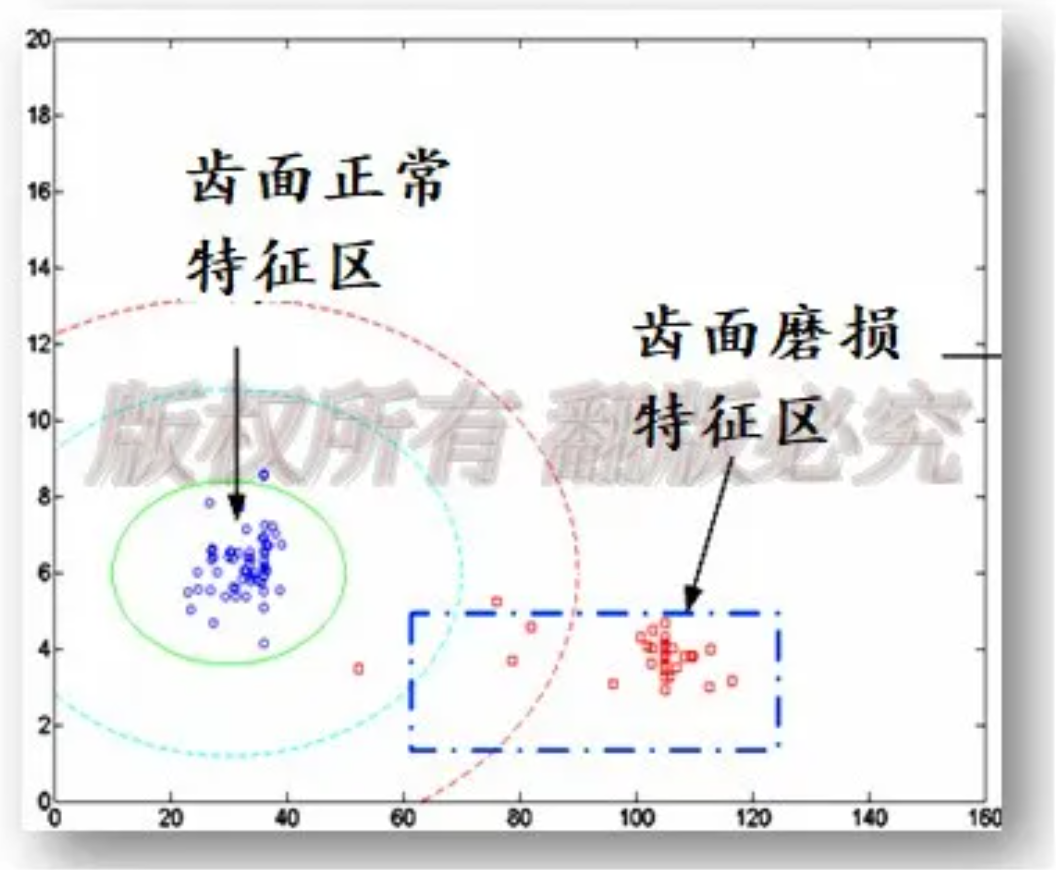

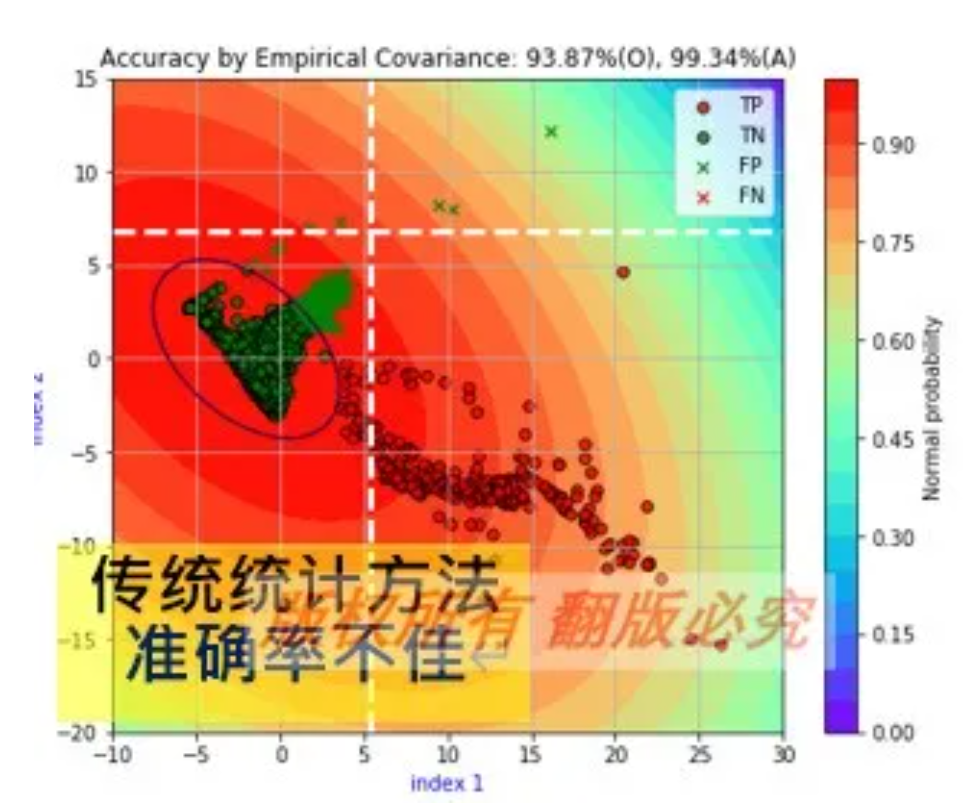

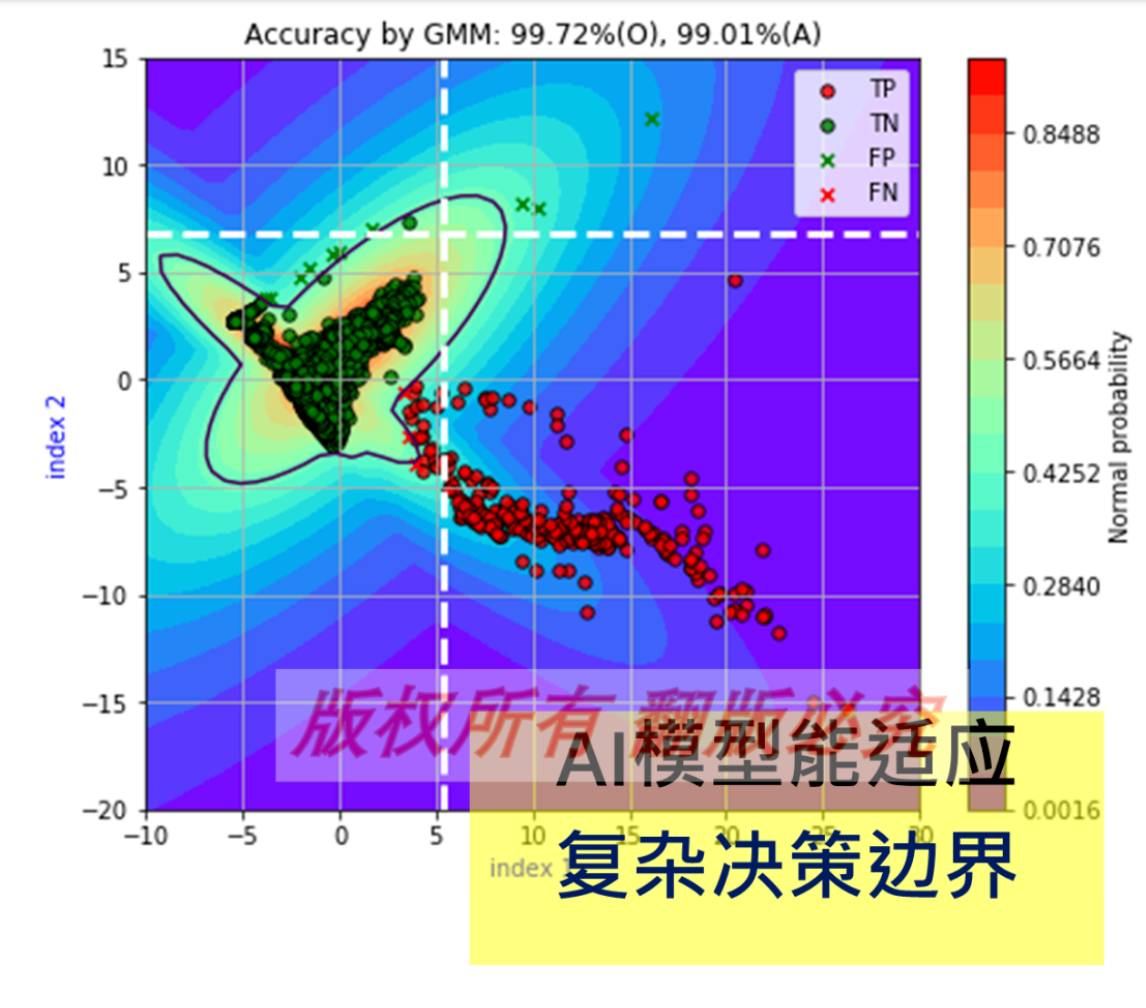

Application Case 2 Reducer gear wear

Application benefits

Discover potential faults early and do premonitorial maintenance.

Clarify the real cause of the fault, further analyze, correct and improve.

Monitor the current status of the equipment and maintain stable operation.

Improve equipment operation capabilities and equipment productivity.

2024-08-26

2024-08-26 ICSC News

ICSC News 上一篇

上一篇