The importance of rolling factory

Roller factories play a crucial role in the steel industry.It is one of the key factors to ensure the safe development of the steel industry.As the main consumable part of the rolling mill,Its performance and quality are directly related to steel production efficiency,Cost and product quality。

Dilemma faced by rolling mills

Application of RFID recognition technology

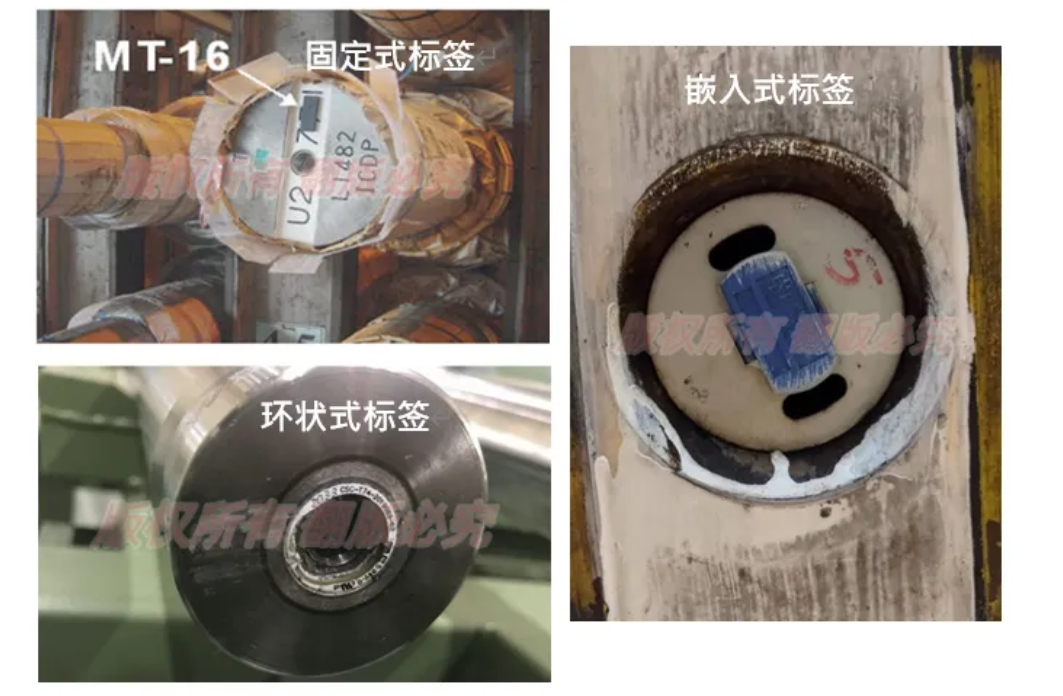

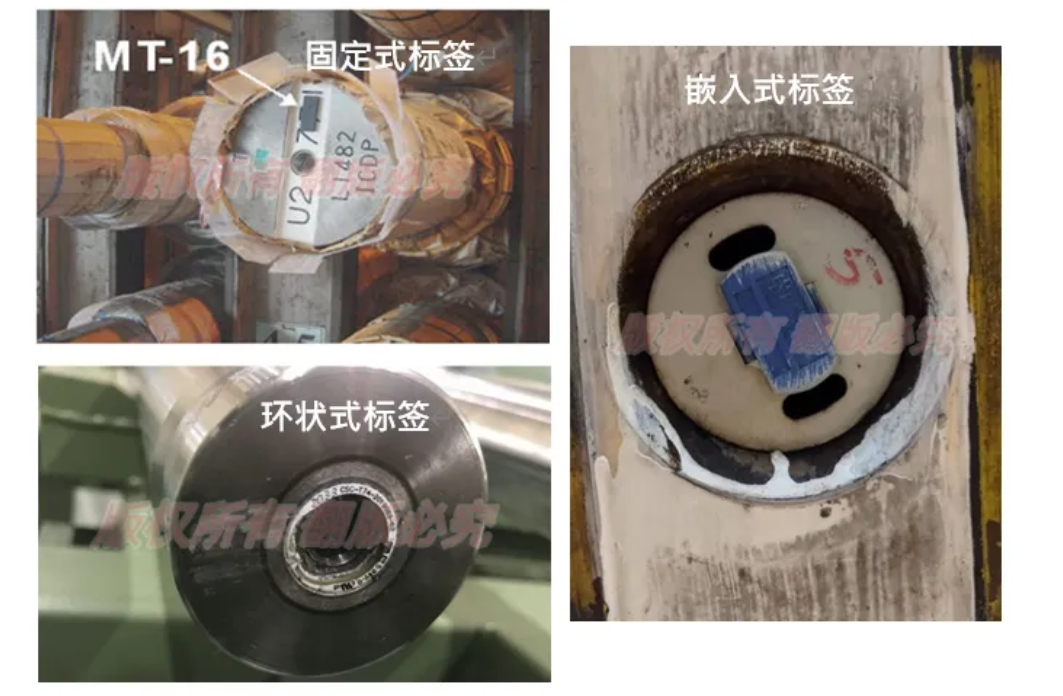

The company has developed fixed and embedded RFID tags that can be used for hot and cold rolling rolls.

Product Features:

Metal resistance

Fixed & snap-on type

Easy to install and not easy to fall

Roller management RFID identification system solution

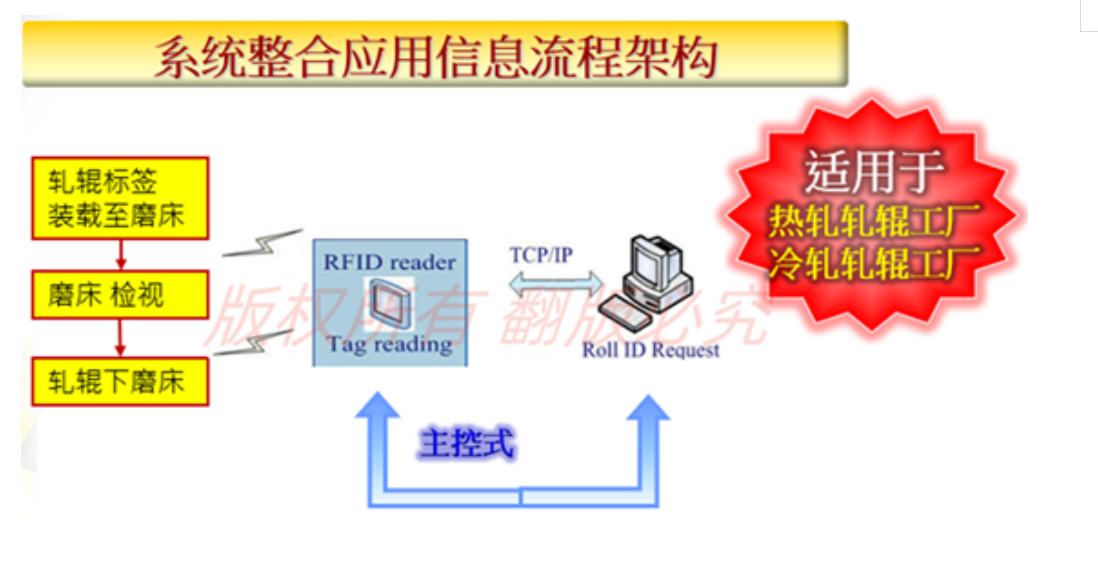

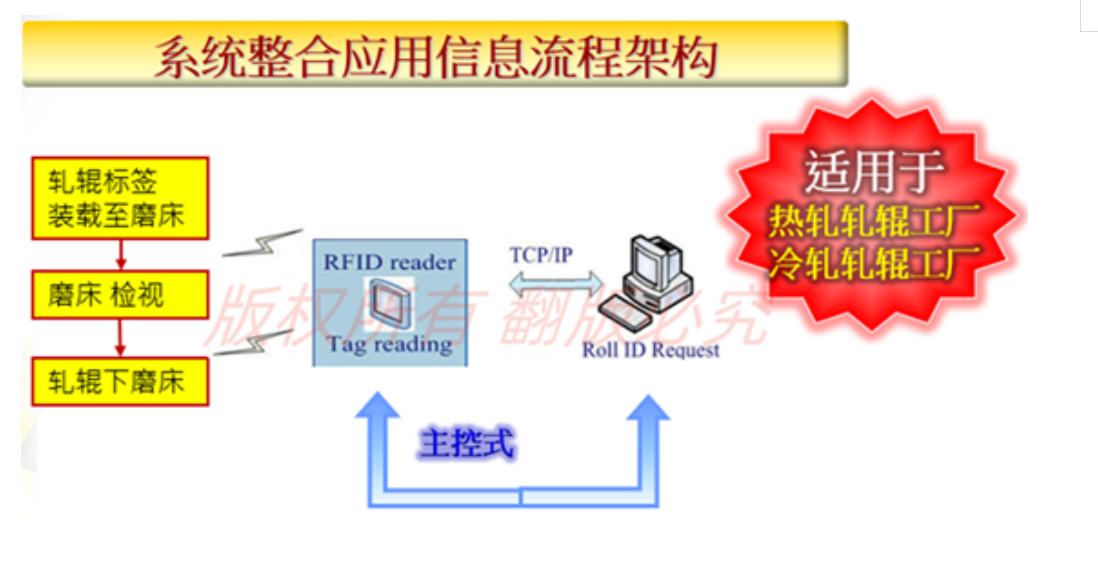

The device's important parameters are recorded in the device's RFID tag, while the position RFID tag is written into the location code, using the RFID reading and writing device and data server information, and directly reading and writing records in the device's RFID tag through the processing of the application software.

Objectives and scope of intelligent management system of rolling factory

Target:

Import the Internet of Things and RFID recognition technology to improve roll operation efficiency

Integrate automatic perception information with advanced management technology to achieve management transparency, automation and refinement

scope:

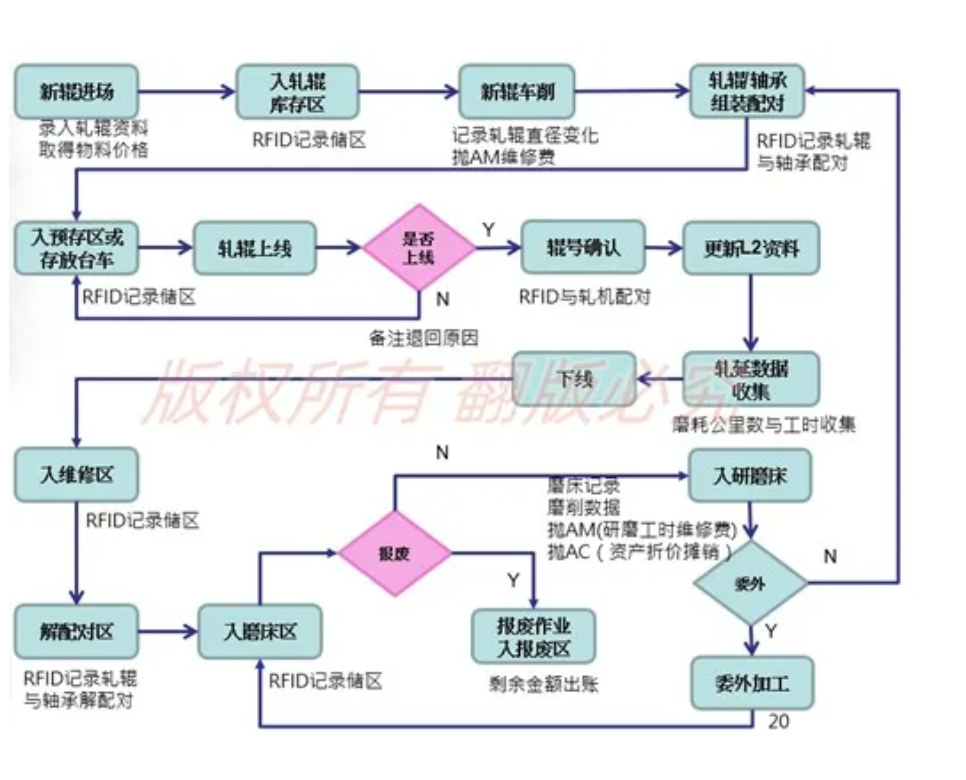

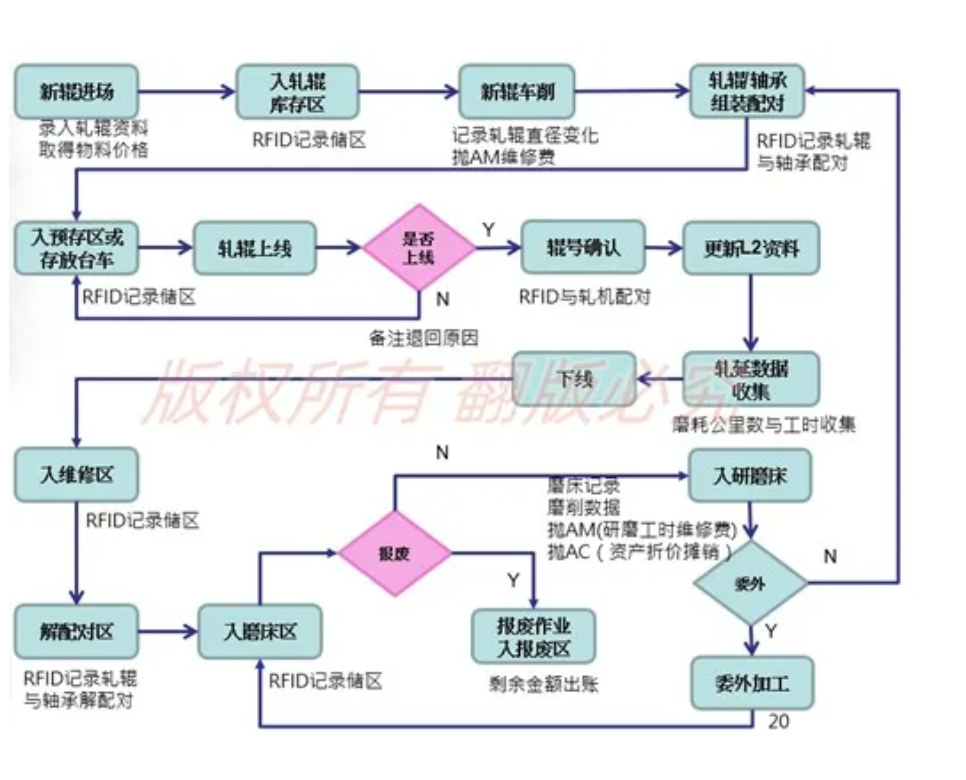

Roll life cycle management from roll purchase until scrapped

Scheduling and management of grinding and rolling extension operations of rolling rolls

Roller life cycle management

Highlights of system functions

Summarize

Summarize

The system uses the RFID roll number identification system to realize electronic management of the roll storage area between rolls to ensure the accuracy of roll information. The roll management information system is used to manage the roll history, including basic data, grinding data, rolling performance data and other related information, as well as automatic transmission of the number between each grinder and each secondary system, and statistics are carried out for the rolling rolls to generate reports. The entire process of rolling roll management is automated through the system.

2024-08-07

2024-08-07 ICSC News

ICSC News

上一篇

上一篇