In the highly competitive industrial market, enterprises are facing tremendous pressure to improve product quality, reduce costs and improve production efficiency. Traditional quality management methods often rely on manual data collection and analysis, which are not only inefficient but also prone to errors. In addition, due to poor information circulation between production links, quality problems are difficult to detect and resolve in a timely manner. These pain points not only affect the market competitiveness of the company, but may also lead to huge economic losses. In response to these problems, the new SPC product launched by ICSC came into being, bringing revolutionary quality management solutions to the company.

1.Comprehensive data integration and analysis capabilities

ICSC SPC products can integrate data from all aspects of the production process, including raw materials, production equipment, process flow, etc., to realize centralized management and sharing of data. Through advanced data analysis algorithms, the system can monitor and analyze various data in the production process in real time and quickly discover potential quality problems. For example, by monitoring the hot-rolled production line SPC system, enterprises can promptly understand the plate shape and coil shape of the hot-rolled coil supplying electrical steel sheets, thereby improving the pass rate.

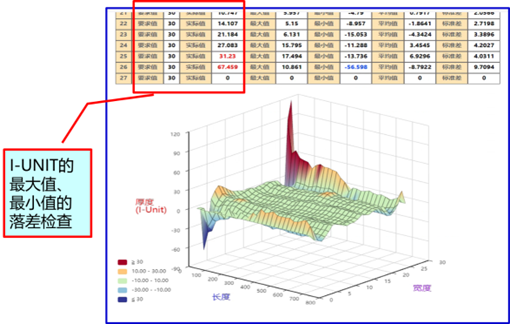

Product three-dimensional graphics

2.Intelligent process control and optimization functions

ICSCSPC products also have the function of continuously improving the process, and can provide suggestions for improving production process parameters based on real-time production data to ensure that the company's production process is in a state of continuous improvement. For example, the system can monitor and master the plate shape and coil shape of the supplied hot rolled coils according to the production requirements of electrical steel sheets, thereby simplifying human resources and improving the pass rate.

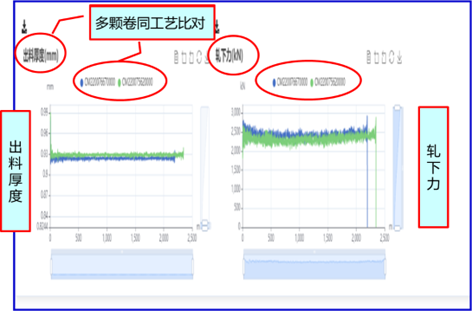

Comparison chart of different products and processes

3.Efficient series process system

In order to better meet the enterprises' needs for upstream and downstream process information, ICSC SPC products have designed a series process system. This system can integrate ERP, SPC systems of each production line and inspection equipment of each production line, allowing the user to easily obtain complete upstream and downstream process and quality information of steel coils. In this way, companies can speed up problem analysis and improve the accuracy and efficiency of decision-making.

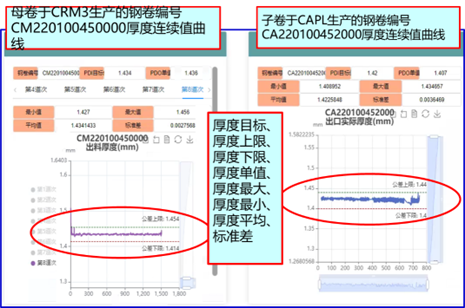

Comparison of process data

4.Strong compatibility and scalability

ICSC SPC products have good compatibility and scalability, and can seamlessly integrate with various existing information systems of the enterprise. Whether it is steelmaking, hot rolling or cold rolling, the system can provide comprehensive data support and management functions. At the same time, with the development of enterprise business, the system can be easily upgraded and expanded to meet the ever-changing business needs.

2025-02-05

2025-02-05 ICSC News

ICSC News 上一篇

上一篇