Intelligent scheduling system is a scheduling solution for applying constraint programming (Constraint Programming) to solve models and mathematical algorithms. Use script-style situational design, set the target function and parameter weights, and perform score calculations when the work restrictions are met. This system can also use the thinking of scheduling personnel to automate and promptly scheduling suggestions for calculation results; in addition, it also provides a convenient and flexible adjustment interface and recalculation mechanism to support scheduling personnel to respond to rapidly changing situations and abnormalities on site.

Using the efficient computing power of computers, comprehensively consider relevant influencing factors to solve problems that are difficult for human brain to integrate

The scheduling results of the production system feasible solution under the fast computing mechanism support the need for re-operation in response to situation changes

Through the intelligent scheduling operation mechanism, people's internal experience is explanatory, external knowledge is standardized, and standard knowledge is optimized.

Build an optimized scheduling operation platform for graphical and elastic adjustment to solve the inconvenience of personnel fine-tuning

Setting and input (INPUT): Each setting includes scheduling parameters, scheduling script, grouping, sorting, impact factor weight, scheduling restrictions, scheduling parent data, maintenance plan, machine time capacity (related time)

Scheduling engine (PROCESS): pre-processing model (data analysis, processing), balanced strategy model, sorting model, jump rolling, inserting and rolling processing module, WKM/PST calculation module, post-processing module, etc.

Schedule result display (OUTPUT): Execute progress monitoring, scheduling result query and adjustment, numerical graphical display of impact factor, rolling and COFFIN graphical display, insertion and rolling operations, violation of rules, scheduling issuance and confirmation, etc.

System connection (LINK): connection of order data, material source data, scheduling results, production performance and other information

benefit

1. Reduce personnel scheduling time and avoid human errors

2. Learn the behavioral patterns of scheduling experts to achieve business experience inheritance

3. Causes and warnings when violating schedule restrictions

4. Reduce the use of overlapping materials and reduce production costs

5. Graphical operation interface improves user experience

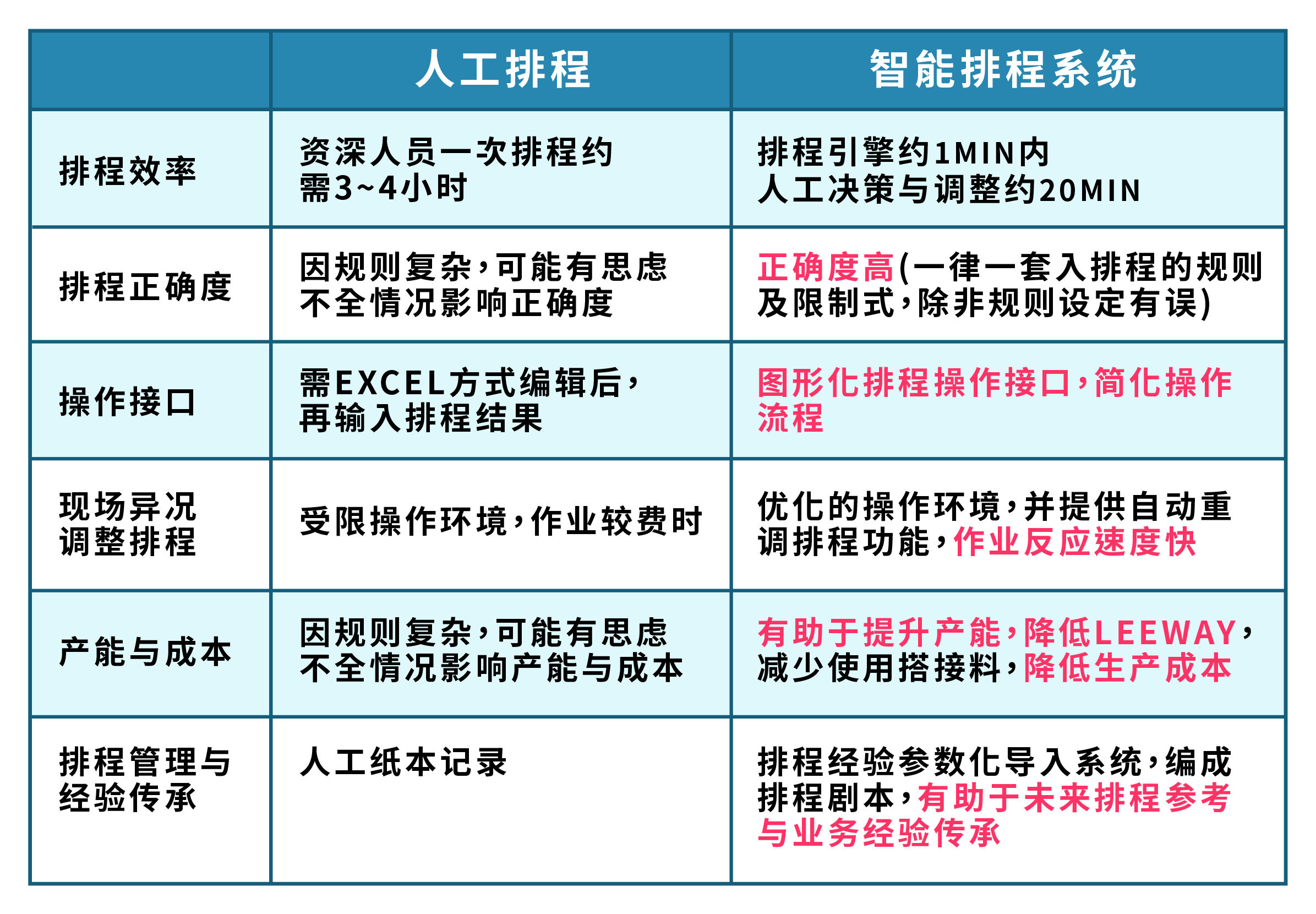

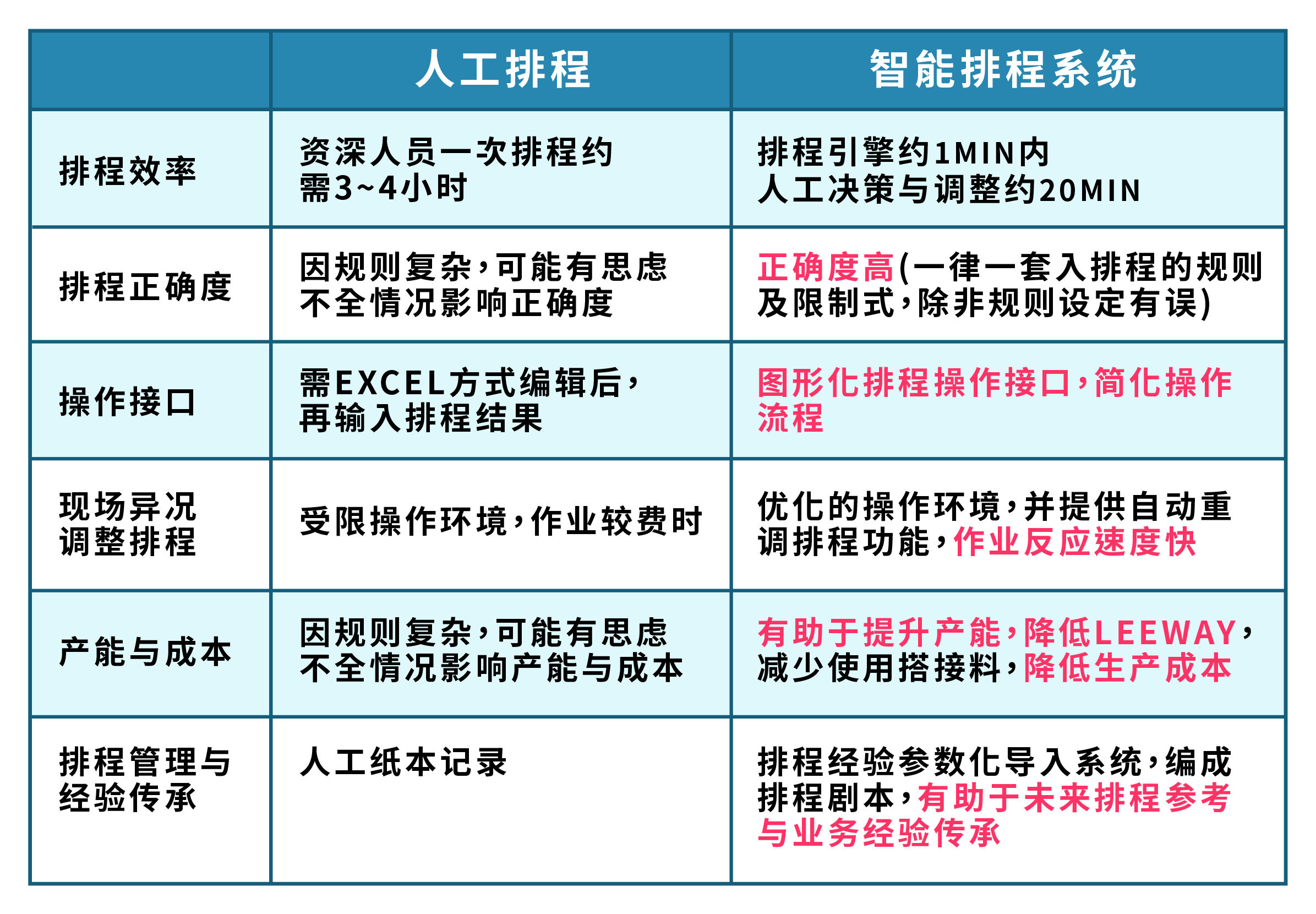

Comparison with manual scheduling: