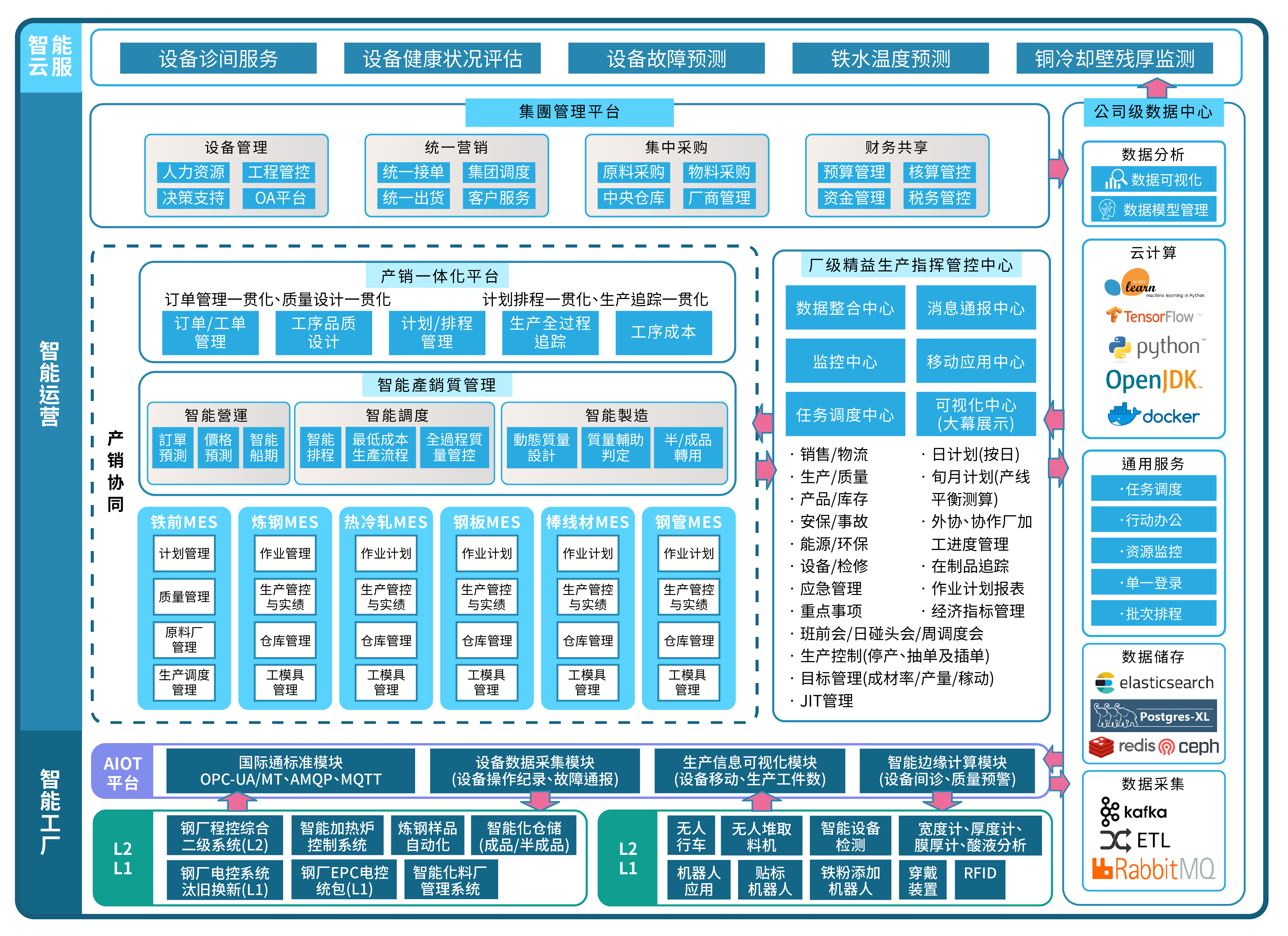

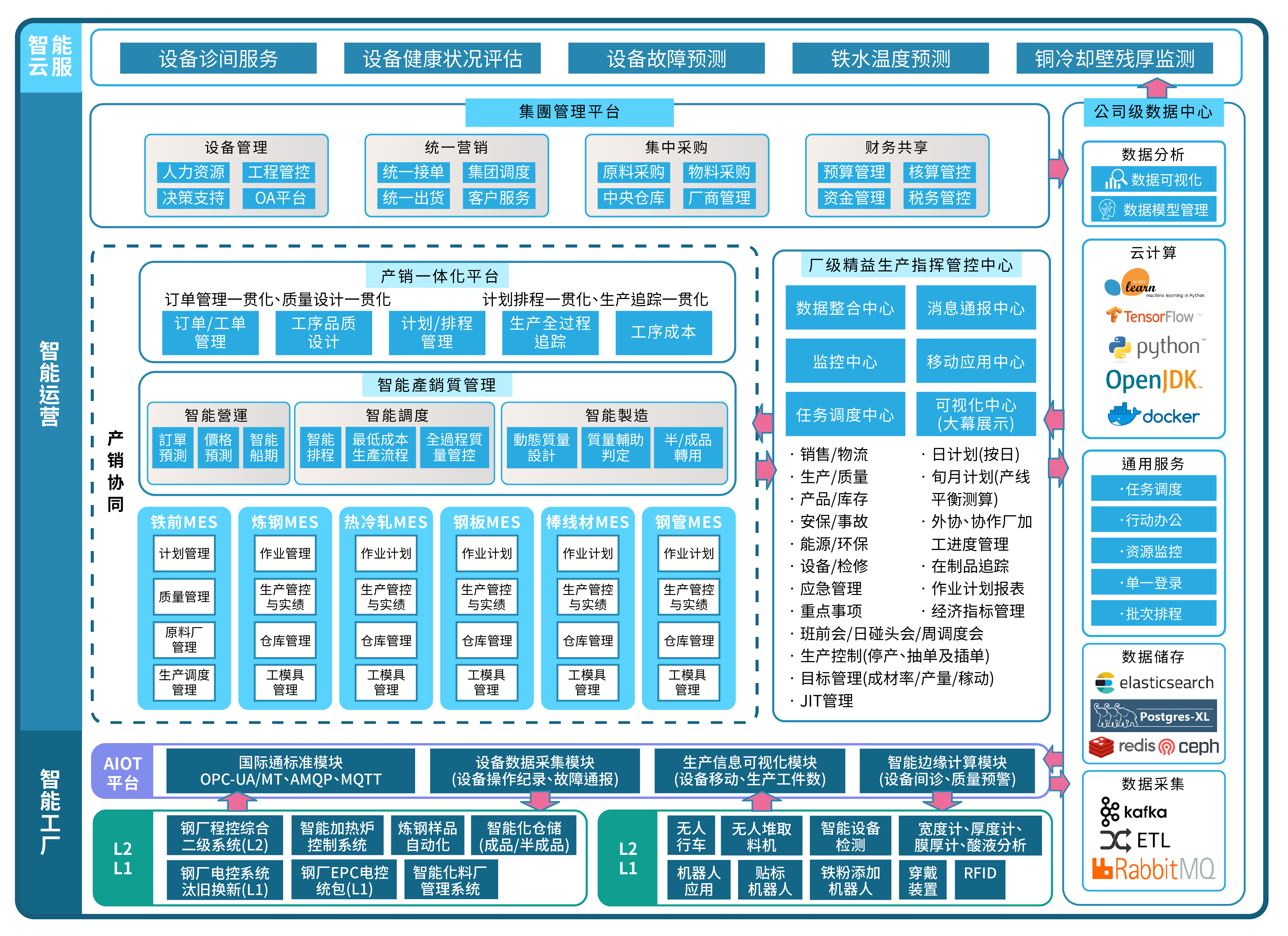

ICSC's integrated production, sales and quality solutions are based on the successful experience of industrial informatization and intelligence in the parent company (Taiwan Zhonggang, 1971~) in the past fifty years, using contemporary mainstream JAVA technology and adding the latest information application concepts, and are developed and completed. This solution is the core of intelligent operations in the steel industry. It can be integrated with the group management and can be connected with the MES when it is extended upwards. The accumulated transaction data can be used for various value-added applications and big data applications in lean production.

Increase profits

Increase production

Increase per capita steel volume

Reduce production costs

Improve inventory turnover

Improve product quality

The enterprise operation process is systematically solidified, and information is real-time and transparent, improving the speed and quality of management decisions

Inheriting the parent company's nearly 50 years of information and intelligence experience and more than 20 years of successful experience in external case services, it is enough to provide various customized solutions for steel companies on the integration of production, sales and quality.

Consistent quality design, building a complete product specification and metallurgical specification system for steel enterprises

Consistent production tracking, providing real-time order tracking system for steel enterprises

Provide cost accounting data and support process cost accounting

Supports connection with various heterogeneous platforms, which can ensure that customers have existing investment and are expandable

The own R&D team ensures that the source code is completely independent and intelligent property rights

The own maintenance team can provide warranty services or program code transfer services