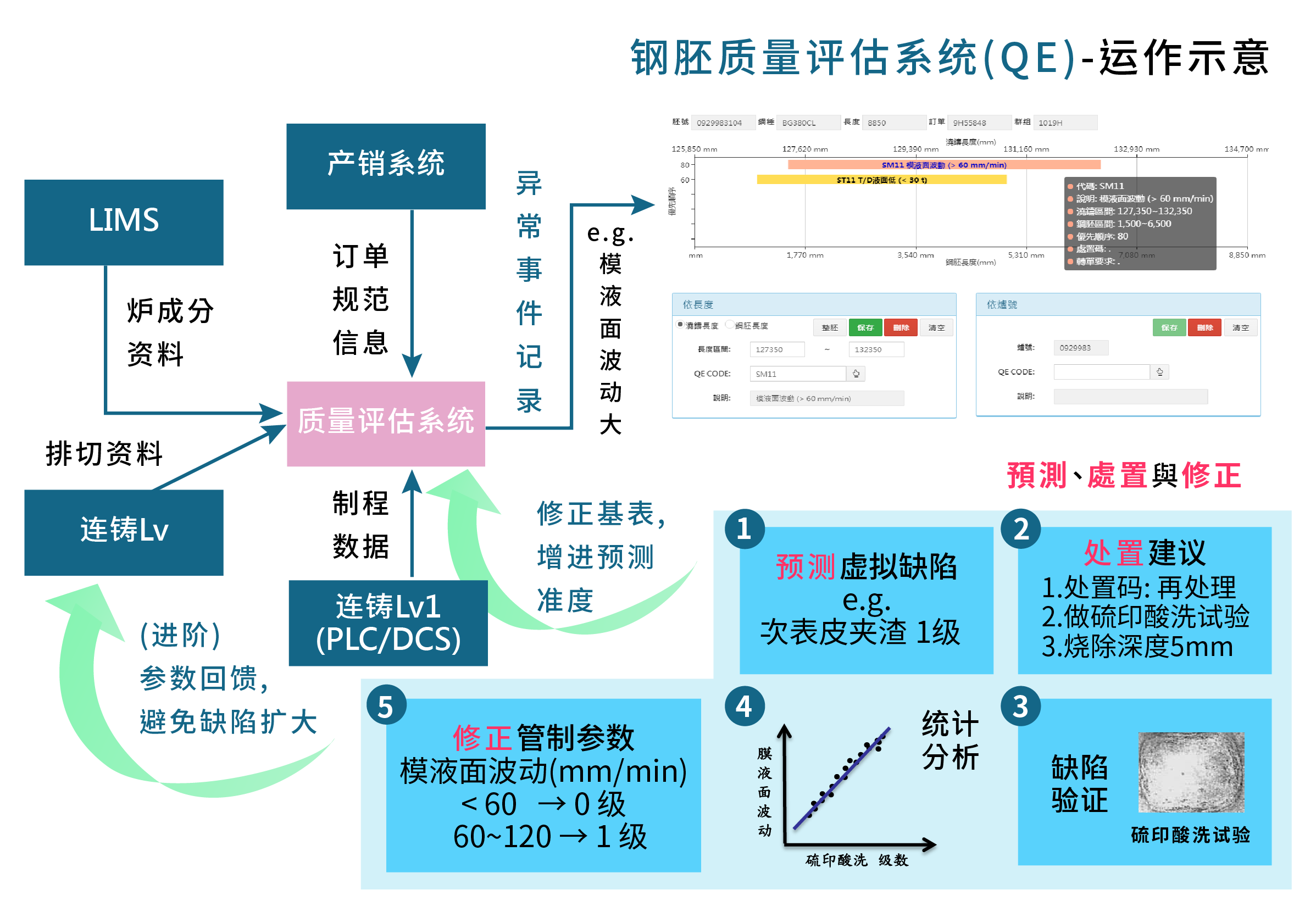

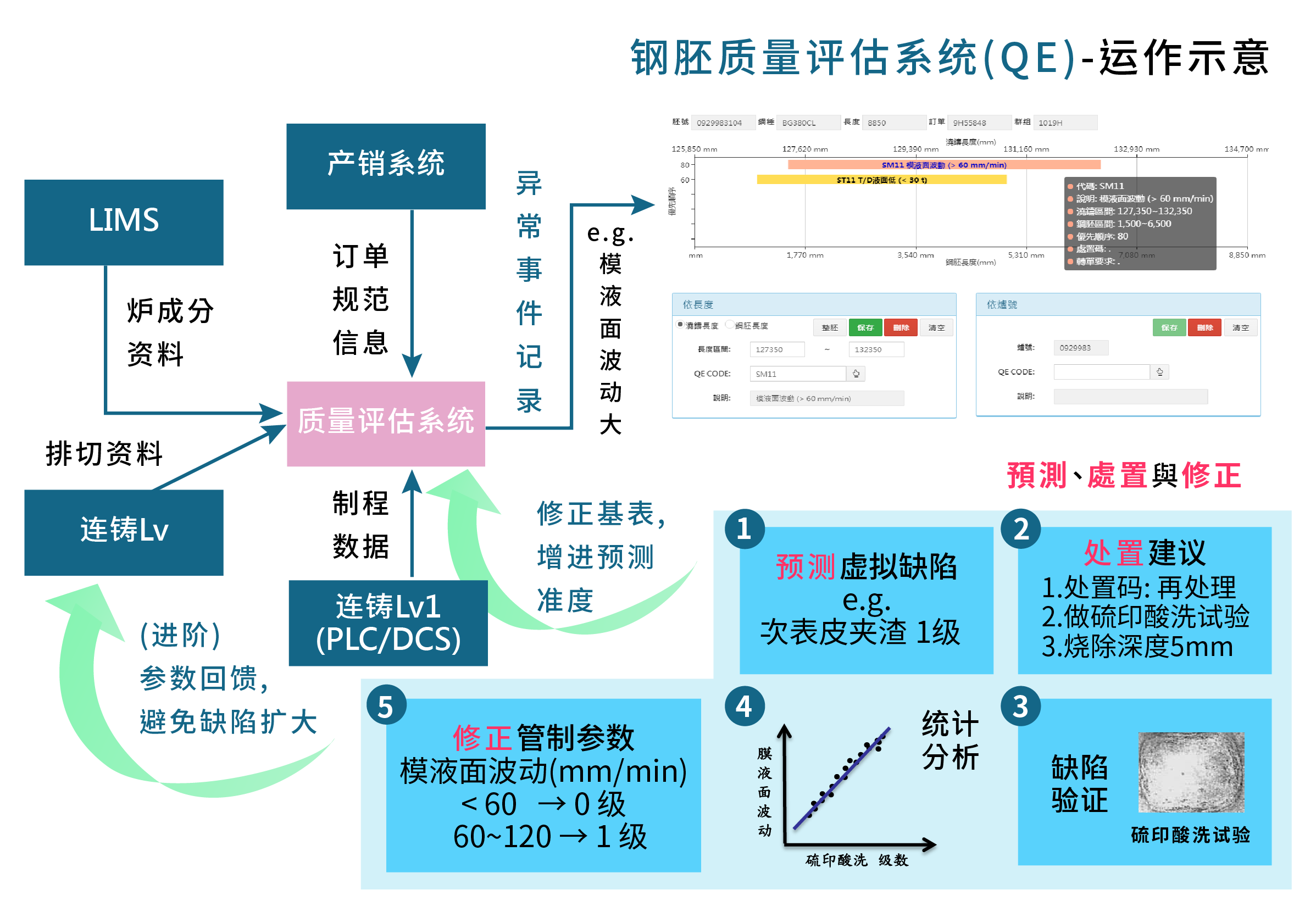

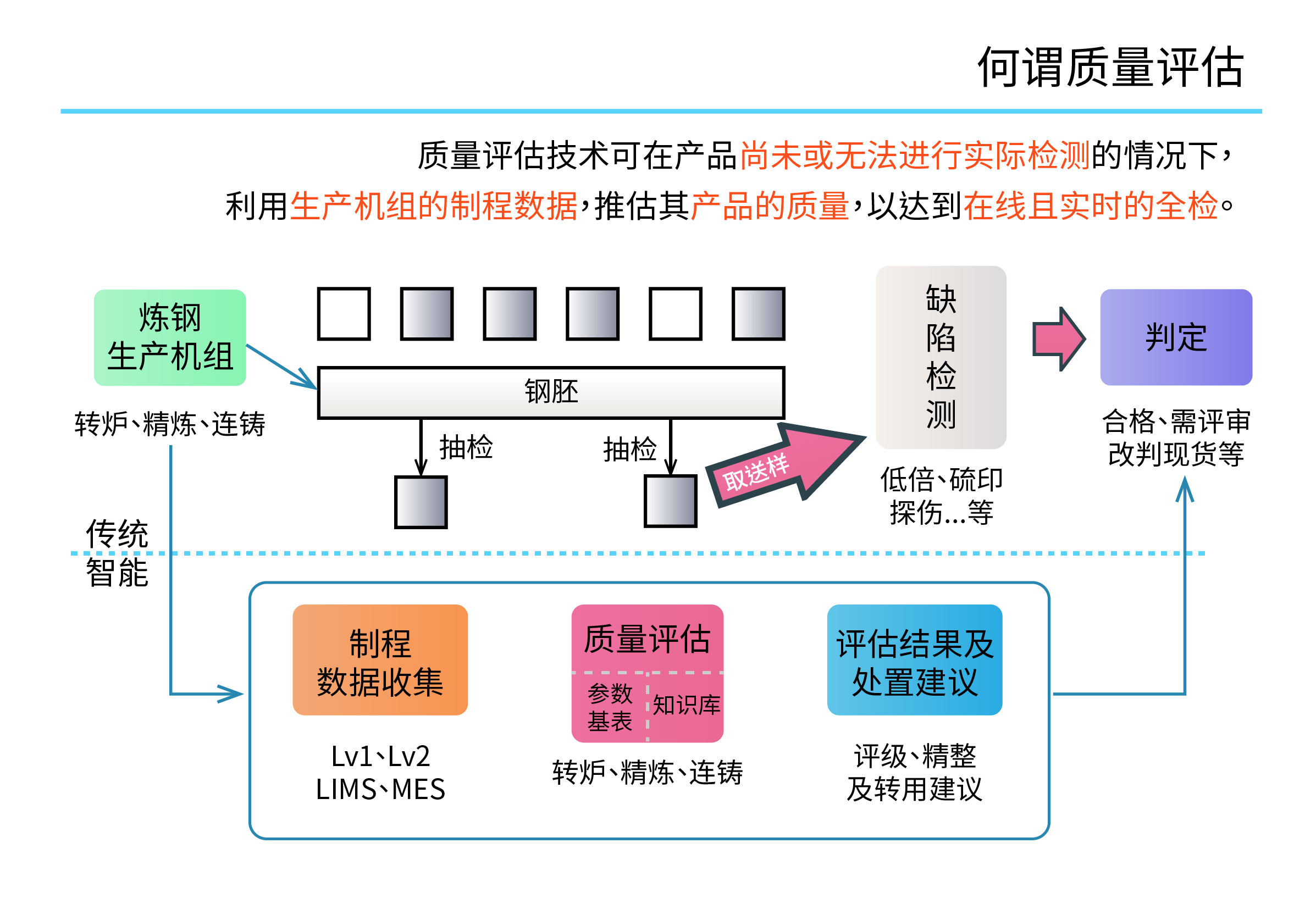

The quality of steel embryos mainly focuses on the components, appearance and inner and outer elements (including internal cracks, central segregation, sub-surface slag inclusions, surface cracks, etc.). The components are determined in the steelmaking and refining process, while the others are determined by continuous casting. During continuous casting, various process conditions and control values can be used to evaluate the quality of steel embryos. Based on the evaluation results, we can quickly grasp the defect status and prevent the inflow of defective products to achieve the purpose of rapid release of steel embryos.

System functions

Monitoring and query: current quality assessment records, historical quality assessment records, laboratory analysis data, equipment operation data

Maintenance of parameter base table: classification group maintenance, abnormal event maintenance, quality evaluation code maintenance, handling suggestions maintenance, virtual defect maintenance

Data connection and collection: data connection of the overall information system, data connection of the assay and analysis data connection, data connection of the equipment operation data collection

System function feature description

Traditional operating model: Traditionally, most steel embryos need to be cooled and tested and burned. Only after confirming that the steel embryo is of normal quality can it be released to the rolling mill for rolling and delaying; steel embryos that are abnormal are refined and processed, so the operating time is often several days, which causes secondary handling and increases production costs.

Intelligent operation mode: Steel embryos can be released directly through online inspection. In addition to reducing the energy consumption of the heating furnace, it can also accelerate logistics. When an exception occurs, the disposal plan can be sorted and filed based on practical experience. When a similar situation is encountered next time, it can be used as the basis for disposal of the exception.

Application benefits

Cost reduction: reduce the number of inspections, protect equipment and personnel, summarize and summarize disposal experience and reduce costs

Early warning: Discover and resolve problems early to prevent the expansion of the risk of quality disability, and ensure that the availability of steel embryos meets the improvement of

Disposal: For steel embryos that have been detected abnormal, suggest re-test or re-treatment remediation measures to reduce the inventory and capital backlog of overflowed steel embryos

Improvement: Accumulate past production performance and quality assessment information as a driving force for continuous quality improvement