Service Introduction

The metal processing industry is part of the basic people's livelihood industry. There are more than 200 members of the domestic steel industry association, and other metal processing industry operators who have not joined the guild should be more than several times. The fierce global competition environment, borderless and zero tariff-free trade freedom makes it more difficult for small and medium-sized enterprises to survive. The main products of domestic related large, medium and small cutting-related processing factories are cutting and processing of steel and coils. In addition to their own products, they are also engaged in OEM business. In the Internet era where information transmission is very fast and easy, customers located in every corner of the world can easily check product specifications and prices, and compare prices and order them in a blink of an eye. There are only two ways for enterprises to obtain profits: one is to reduce costs; the other is to differentiate.

Reduce costs

Enterprises can examine the fixed and variable costs at each stage in the internal operating process of the product value chain and strive to reduce fixed costs. However, before proceeding with this step, the company must make sure that the data obtained is correct and consistent. Only in this way can the right medicine be prescribed.

Differentiation

Enterprises can provide differentiated products or services based on customer needs. New product research and development requires a large amount of resources, including manpower, material resources and time; but rapid response to customers can be achieved in a short period of time. Whether it is order specification confirmation, delivery commitment, product information and after-sales service, it can be collected and provided through information integration. Both of the above methods require the support of the information system. The daily operation and transactions of the enterprise are complicated. Through the recording, calculation, summary, analysis and feedback of the information system, the enterprise can be provided with complete operating information and assist operators in making correct decisions; through the system construction, the information required by customers can be provided on the Internet to create customer independent satisfaction! In the current era of informationization, the domestic cutting industry may have used some related information systems, but due to the independence of systems, the daily changes in business needs cannot be supported immediately and effectively. Therefore, it is necessary to integrate and manage information such as production and sales, raw materials, accounting, costs, human resources, equipment, etc., so as to improve efficiency, increase profits, and enhance competitive strength. Therefore, the update and establishment of the overall information system is imperative.

Both of the above methods require the support of the information system. The daily operation and transactions of the enterprise are complicated. Through the recording, calculation, summary, analysis and feedback of the information system, the enterprise can be provided with complete operation information to assist operators in making correct decisions; through the system construction, it can also provide the information needed by customers on the Internet to create customer autonomy and satisfaction.

In the current era of informationization, the domestic cutting industry may have used some related information systems, but due to the independence of systems, the daily changes in business needs cannot be supported immediately and effectively. Therefore, it is necessary to integrate and manage information such as production and sales, raw materials, accounting, costs, human resources, equipment, etc., so as to improve efficiency, increase profits, and enhance competitive strength. Therefore, the update and establishment of the overall information system is imperative.

System architecture planning

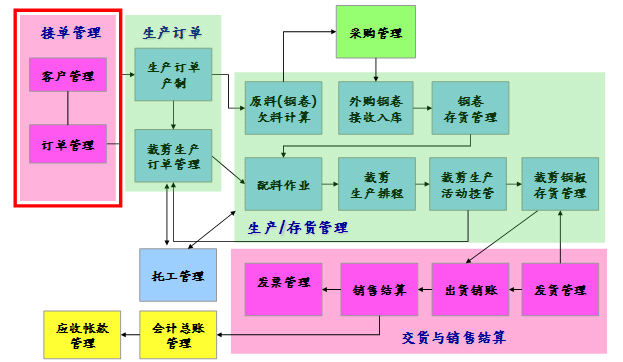

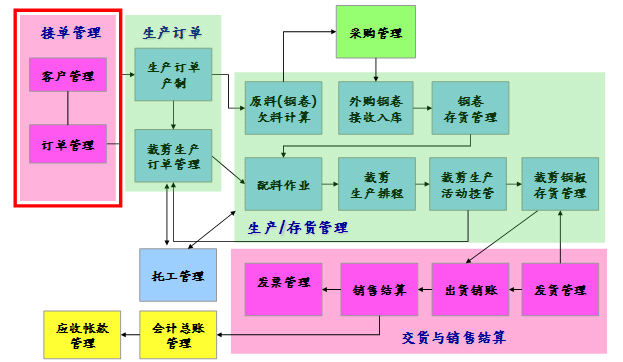

This system includes sales management, production management, purchase and storage management, accounting management and information operation management. The relationship between system architecture and domain and system functions are described as follows:

Architectural planning of production and sales fields

Solution benefits:

Construct and implement efficient cutting production and sales mechanisms.

Electronic signature and credit management improve the quality of order acceptance.

Product specification parameterized management overcomes product specification changes environment.

Convenient and accurate delivery planning operation management.

Real-time production status information specifically controls the pulse of order production.

Flexible and simple and accurate shipping and accounting operations management.

Multifunctional characteristics of ingredients improve production efficiency.

Elastic production activity control effectively shortens the production time.

Accurate inventory information to improve inventory management performance.

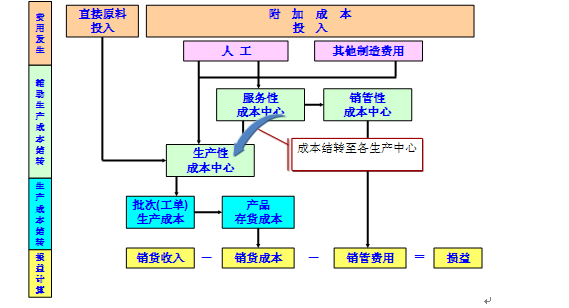

Cost field architecture planning

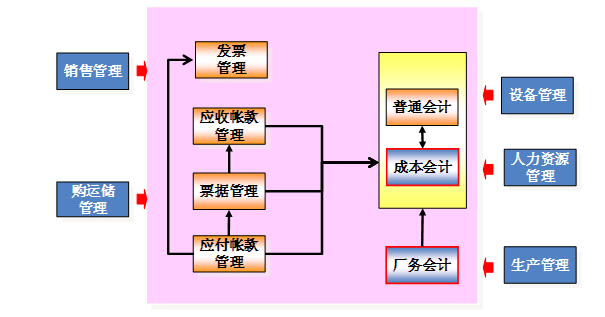

Architectural planning in the accounting field

Solution benefits:

Receivables that can be followed by the context, and process management:

1. Receivable, the handling process is automatically connected by the system

2. Provide tracking and ageing analysis of receivables and payables

3. Real-time response to reduce corporate operational risks

In terms of source input, all data are automatically transmitted by the system via the standard interface.

1. When inputting from the source, the data will be checked to avoid the generation of incorrect data. The system will not correct it later, increasing the burden.

2. Reduce the labor of repeated input

3. Avoid the opportunity of data entry errors

Flexible accounting statement setting

1. Reports can set headers, rows, columns, and calculation formulas, and can be set elasticly by themselves.

2. Report calculation and printing are separated, rather than recalculating each time it is printed. This not only saves recalculation time, but also retains the last printed data.

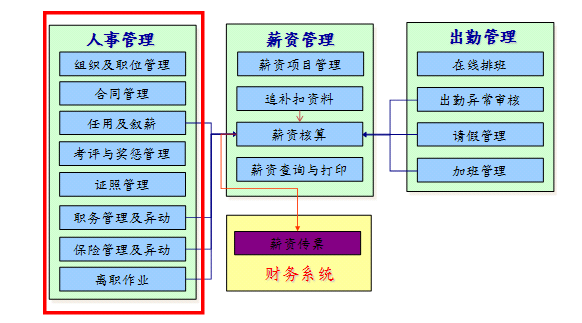

Human Resources System Planning

Solution benefits:

Take position as the core of management

Complete employee career record

Keep track of attendance at any time

Easy to operate salary calculation

Real-time information improves personnel management efficiency

The system automatically transfers subpoena to improve administrative efficiency.

Equipment field architecture planning

Solution benefits:

Improve the quality of repair decisions for equipment or spare parts

Automatically generate maintenance plans and material collection applications

Automatically prompt for safety procedures and control cards on the work order

Maintenance knowledge platform to speed up repair capabilities

Simplify steel plant processes and facilitate personnel operations

Elastic modular function, quick reinforcement of system functions

Raw material procurement planning

Solution benefits:

Closely combine the accounting system and inventory system, and combine the information in the purchase order with the inventory system information to ensure accuracy, consistency and data integrity, provide the latest status of various inventory and material changes, automatically generate accounting vouchers, master real-time information and procurement inventory costs, and achieve integrated impact by connecting to the financial management system.

Authorize control, prevent errors and post-audit audits, set operation permissions, ensure data security according to user instructions, provide purchase order operation to enable online input, save input time, avoid errors, improve data accuracy, maintain complete data benefits post-audit audits, provide complete management functions and provide efficiency. Provides complete management functions to help decision-making and provide a full process of transaction status from ordering, delivery tracking, acceptance and reimbursement, and settlement. The procurement management system can provide query functions related to purchase orders, requirements and delivery and management reports.

Procurement, distribution and storage management provides a comprehensive application module that collects order-related information, receives and inspects, inventory, and provides various management reports, which not only saves a lot of manual operations, but also avoids repeated input errors and delays due to all data being entered from original data and real-time detection.