ICSC Steelmaking Dynamic Scheduling System: An Intelligent Solution to Improve Production Efficiency

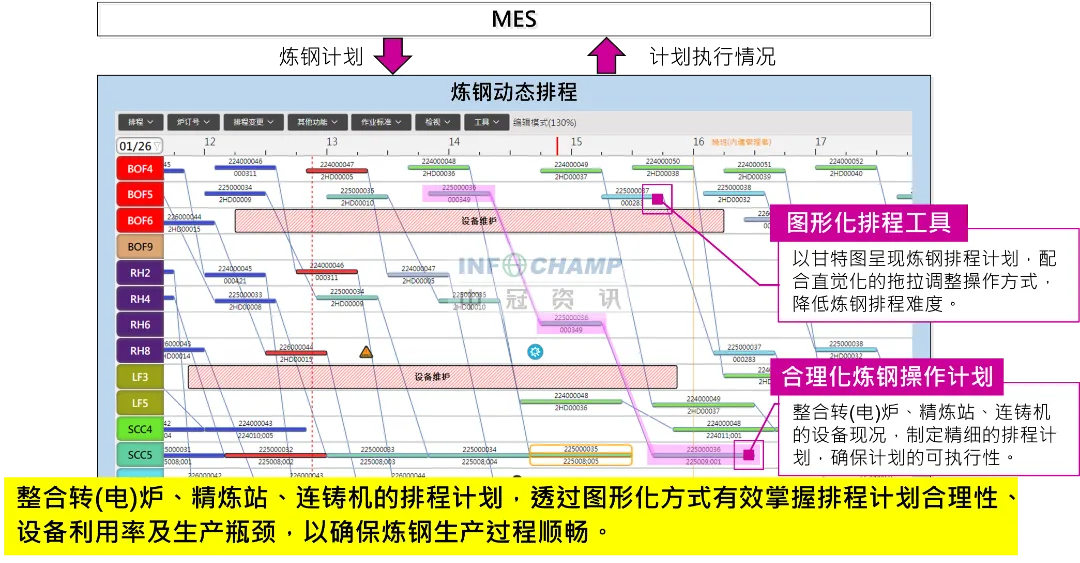

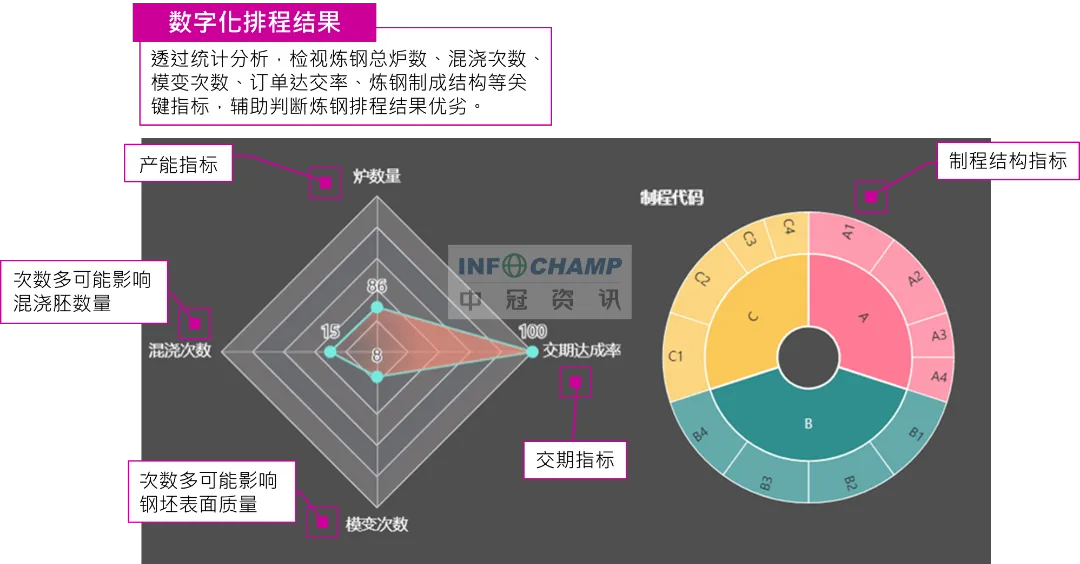

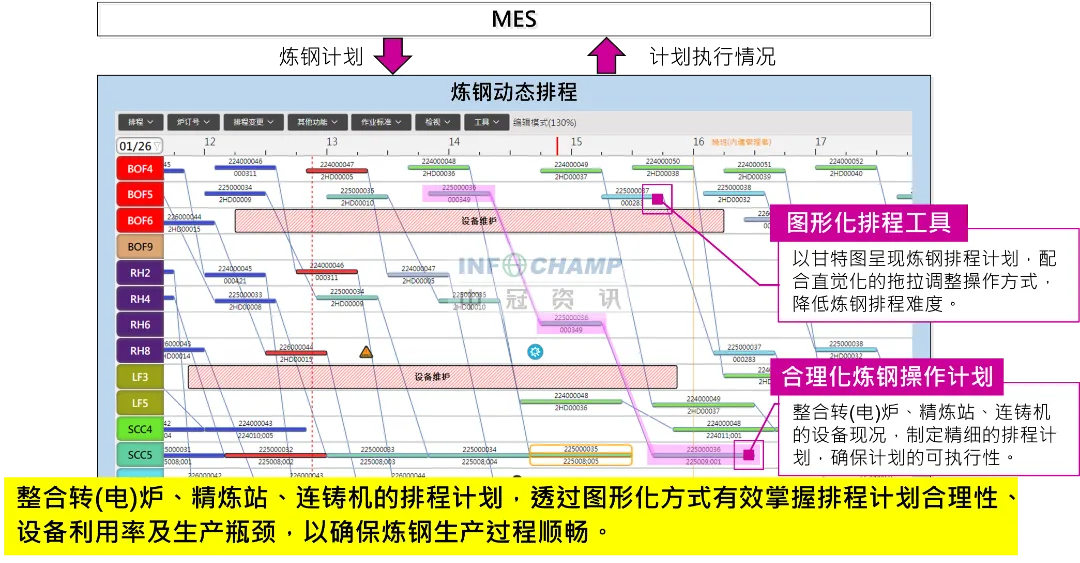

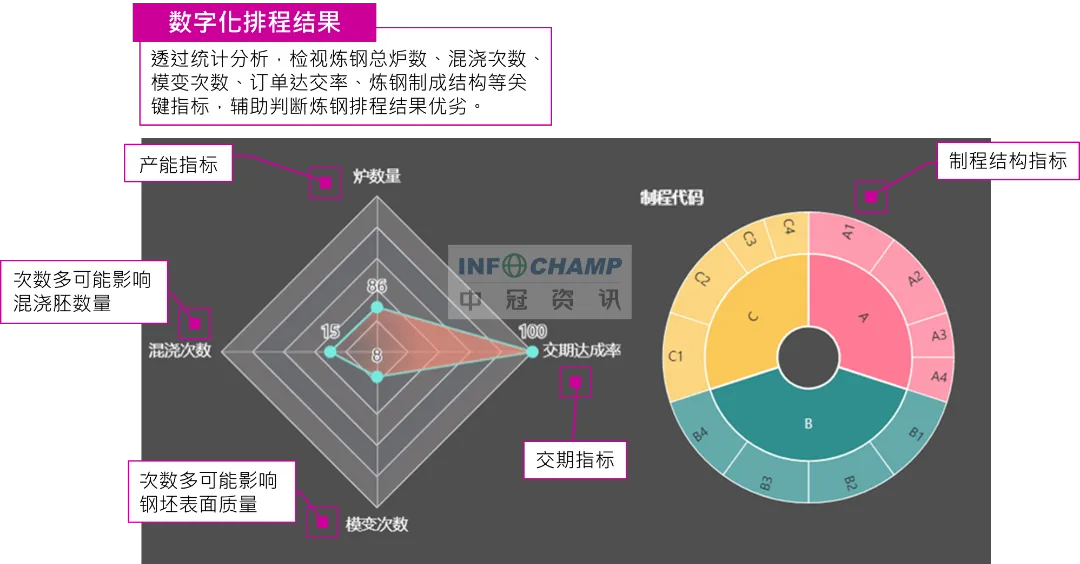

In modern steel production activities, the steelmaking process involves multiple converters, refining equipment and continuous casting machines. The on-site situation is complex and changeable, and the time is extremely urgent. Traditional manual scheduling methods are difficult to cope with these challenges, which easily leads to production stagnation and cannot effectively increase production. To solve these problems, we have launched an advanced dynamic steelmaking scheduling system, which presents steelmaking scheduling plans through graphical tools and Gantt charts, simplifying the operation process and ensuring efficient production operation.

Core functions and advantages

Graphical scheduling tools:

The intuitive Gantt chart displays the steelmaking schedule, making the complex production process clear at a glance.

Supports intuitive drag and adjustment operations to reduce scheduling difficulty and reduce human errors.

2. Equipment status integration:- Monitor the equipment status of converter, refining station and continuous casting machine in real time, and formulate a detailed schedule plan.

- Ensure the execution of the plan and avoid production delays caused by information asymmetry.

3. Strain time requirements:- Real-time adjustment functions are provided for sudden abnormalities in steelmaking fields, such as production equipment failures, cyclone failures, component inconsistencies, etc.

- Solve current problems in a short time, and optimize subsequent production plans to ensure the continuous and efficient operation of the production line.

4. Transparent production process:- Each site can prepare in advance according to the schedule to reduce waiting time and resource waste.

- Each unit can fully grasp the equipment status and production status and improve overall coordination efficiency.

5. Online real-time control:- Relevant units, offices and production planning departments can all grasp the real-time production status on site online.

- Timely dispatch and response to the production line to maximize comprehensive efficiency and ensure that the production record is clear and clear.

Reduce the work burden of duty supervisors:

Automated scheduling systems reduce the need for manual intervention, allowing managers to focus on more important decision-making and oversight efforts.Simplify production process:

Improve productivity by optimizing scheduling, reducing unnecessary steps and waiting time.Improve transparency:

All relevant personnel can understand production progress and equipment status in real time and enhance team collaboration.

Improve production capacity:

Through refined management and real-time adjustments, maximize the use of production equipment and significantly increase output.Reduce downtime:

Respond quickly to equipment failures and other abnormalities to reduce unplanned downtime.Optimize resource allocation:

Dynamically adjust resource allocation according to actual needs to avoid waste and reduce costs.

In short, the dynamic scheduling system of steelmaking can not only help steel mills cope with complex production environments, but also significantly improve production efficiency and management levels. It is an ideal choice for modern steel enterprises to achieve intelligent and efficient production. Introduce this system now to rejuvenate your production line!

2024-11-22

2024-11-22 ICSC News

ICSC News 上一篇

上一篇