When the steel tank is heated by electrode, the slag line temperature in the barrel will be higher than the liquid steel itself. If the slag line temperature is too high, the wall of the steel tank will be broken, delaying production and increasing production costs. On-site operators generally observe whether there is abnormal redness outside the steel barrel during the refining process. If so, the refining procedure will be stopped urgently and the barrel will be arranged to be offline for maintenance. However, if the on-site personnel do not find it due to other work, or the redness of the barrel body cannot be found due to environmental brightness or other equipment blocking, hole breaking accidents will occur during the refining procedure.

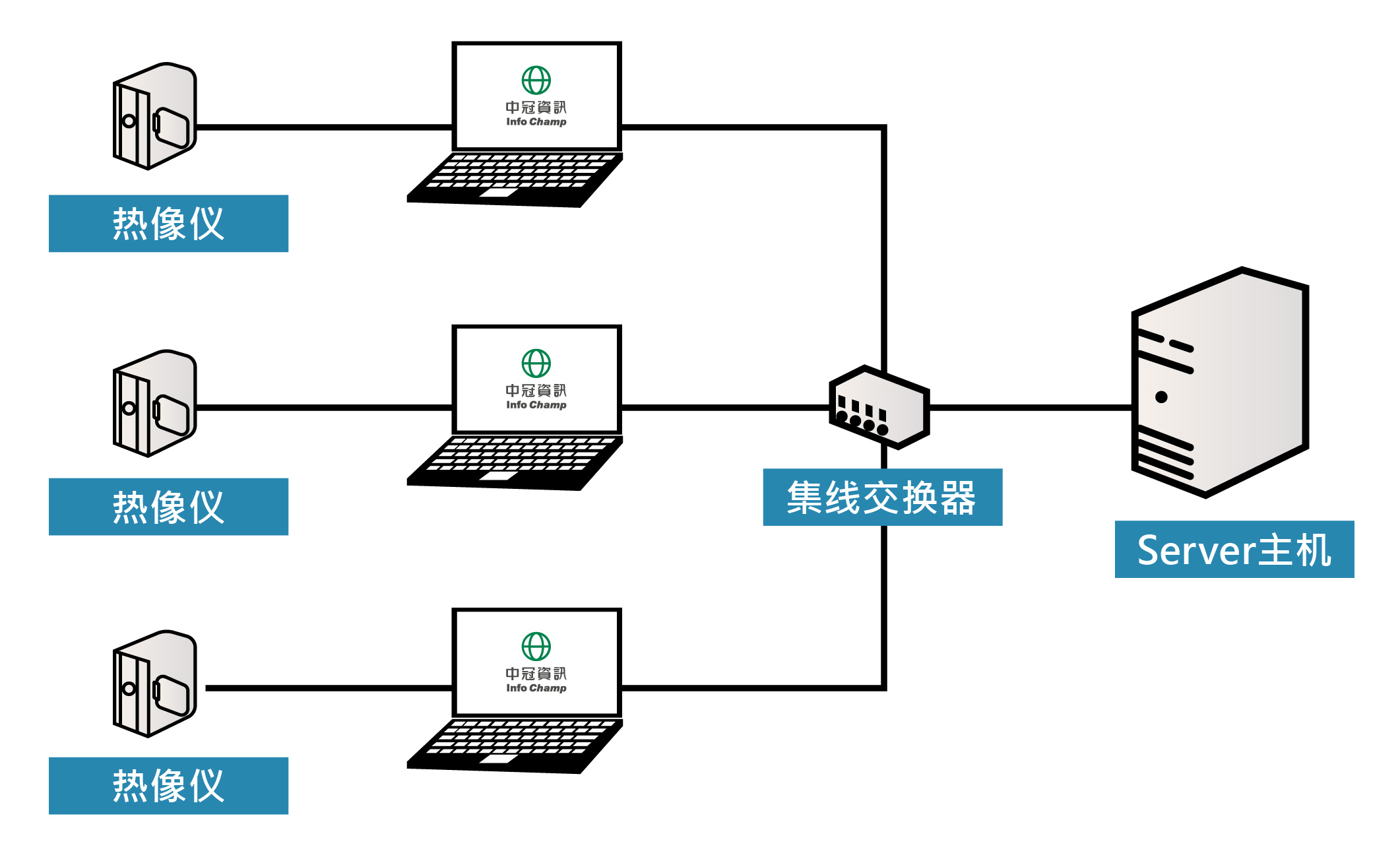

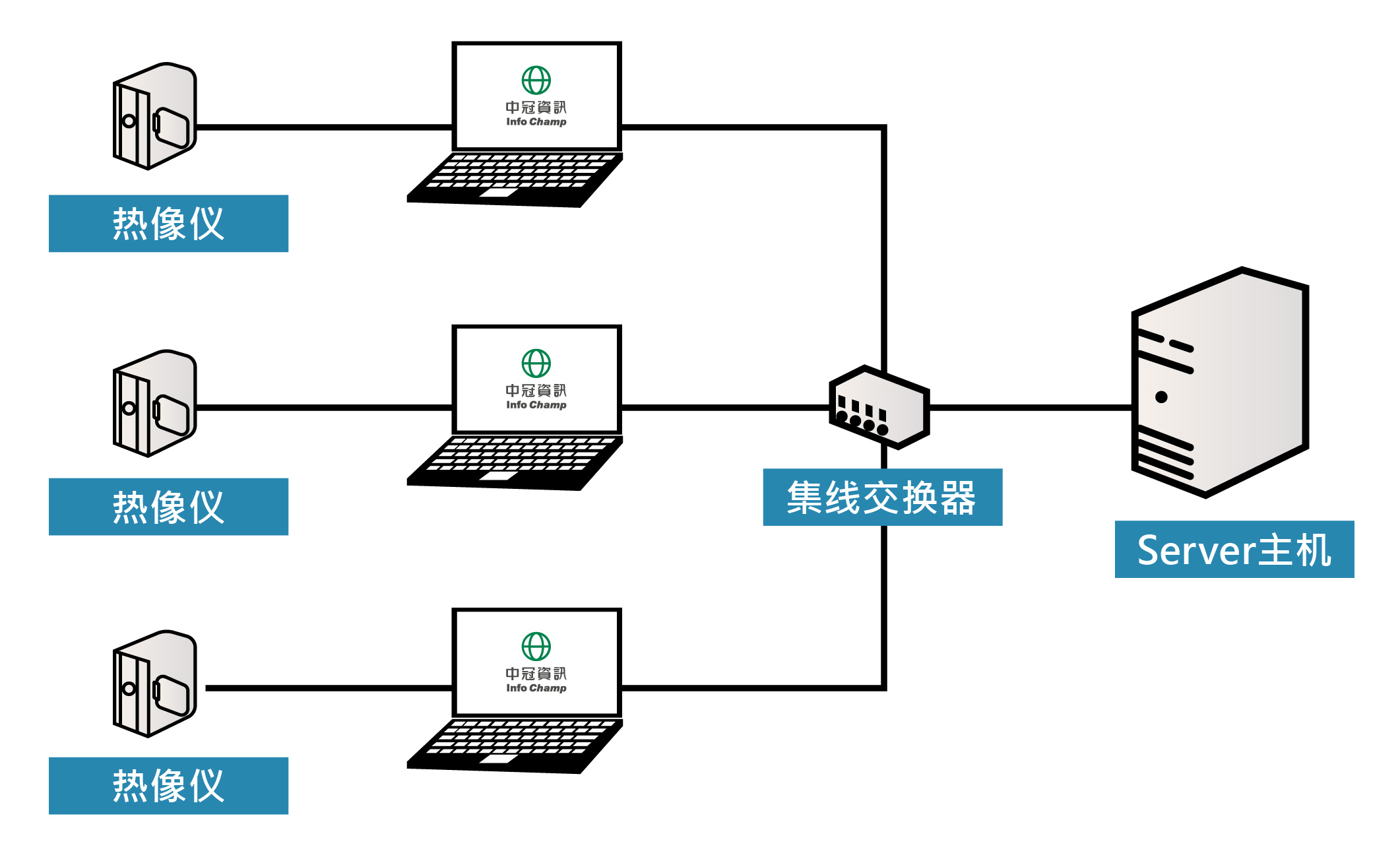

This system will establish a steel barrel hole-breaking warning mechanism to develop detection equipment that prevents hole-breaking through continuous detection during refining to reduce the incidence of this phenomenon, thereby improving personnel safety and production equipment productivity.